DOLD Emergency stop modules SAFEMASTER

| Type | Function | Also suited as safety gate monitor | Cat. / PL acc. to EN 13849-1 1) | SIL CL acc. to EN 62061 1) | 1- / 2- channel | Output contacts, max. | Thermal current Ith [A] max. | Cross fault detection |

Nominal voltage DC AC |

Connec- tion |

Width [mm] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NI 5061 | Emergency stop device | 4 | 42 | |||||||||

| LG 5924 | Emergency stop module 3) | 4 / d | 2 | 1 | 4 NO | 5 | + | + | PS/PC | 22.5 | ||

| LG 5925 | Emergency stop module 3) | + | 4 / e | 3 | 1; 2 | 4 NO | 5 | + | + | + | PS/PC | 22.5 |

|

BG 5924, IP 5924 |

Emergency stop module | 4 / e | 3 | 1 | 4 NO | 7 | + | + | PS |

22.5; 70 |

||

| RK 5942 |

Emergency stop module, most compact design |

4 / e | 3 | 1 | 1 NO | 5 | + | S | 17.5 | |||

| BD 5987 | Emergency stop module | + | 4 / e | 3 | 1; 2 | 2 NO | 10 | + | + | + | S | 45 |

| BG 5925 | Emergency stop module | + | 4 / e | 3 | 1; 2 | 3 NO | 7 | + | + | + | PS | 22.5 |

| BN 5983 | Emergency stop module | + | 4 / e | 3 | 1; 2 |

3 NO, 1 NC |

10 | + | + | PS | 100 | |

| BD 5935 | Emergency stop module | + | 4 / e | 3 | 1; 2 |

3 NO, 1 NC |

10 | + | + | PS | 45 | |

| LG 5928 | Emergency stop module with delay up to 300 s | + | 4 / e | 3 | 1; 2 |

2 NO, 1 NOv |

8 | + | + | PS/PC | 22.5 | |

| BH 5928 | Emergency stop module with delay up to 300 s | + | 4 / e | 3 | 1; 2 |

3 NO, 3 NOv |

5 | + | + | PS | 45 | |

| BI 5928 | Emergency stop module with delay up to 300 s | + | 4 / e | 3 | 1; 2 |

3 NO, 3 NOv |

5 | + | + | PS | 67.5 | |

| BH 5903 |

Emergency stop module with power failure detection |

4 / e | 3 | 1; 2 | 3 NO | 5 | + | + | PS | 90 | ||

| BL 5903 |

Emergency stop module with power failure detection |

4 / e | 3 | 1; 2 | 3 NO | 5 | + | + | PS | 90 | ||

|

BN 5930.48/203, BN 5930.48/204 |

Emergency stop module | + | 4 / e | 3 | 1; 2 |

3 NO, 1 NC |

10 | + | + | PS | 100 | |

| LG 5925/034 |

Safety module for elevator control |

4 / e | 3 | 1; 2 |

3 NO, 1 NC |

2 | + | + | + | PS/PC | 22.5 | |

| Type | Function | Inputs, max. | 1- / 2-cannel |

Nominal voltage UN DC 24 V |

Width [mm] |

|---|---|---|---|---|---|

| BH 5922 | Emergency stop monitor | 8 | 1; 2 | + | 45 |

| BL 5922 | Emergency stop monitor | 16 | 1; 2 | + | 90 |

DOLD configurable safety system - modular and multifunctional.

With the size of the plants and complexity of the safety requirements the number of safety devices increases in many applications. In addition logical functions need to be implemented when e.g. only parts of the whole system needed to be disconnected. The modular and configurable safety system SAFEMASTER PRO of DOLD monitors the safety circuits of your machines and plants simple, flexible and safe. The number of inputs and outputs of the central control unit can be amended by extension modules. In this way SAFEMASTER PRO can be configured very flexible to the actual application. The configuration of the TUEV approved system is done very simple on a PC with the free configuration software SAFEMASTER PRO Designer: Select safety functions, assign in and outputs and connect them comfortably by PC. Finally transfer the tested logic via USB cable to the safety controller.

Configurable safety system.

- Compact design: Control Unit and Extension modules only 22.5 mm width

- Max. 128 safe inputs and 16 safety related outputs

- In addition to the Controller unit max. 14 extension modules can be connected

- Flexible safety logic to create and amend the safety functions

- Safe integrated logic testing

- Monitoring outputs, status LEDs and field bus connection to provide best diagnostic functions

- TÜV and UL approval

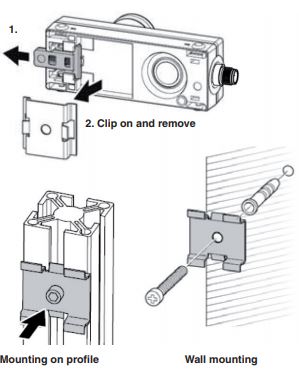

Dold emergency-stop-device assembly and commissioning.

Dold - Your solution provider for safe automation, electrical safety and smart drive technology.

DOLD develops tailor-made solutions for individual customer applications in the field of safety technology. In addition to a large number of devices with standard functions, we offer many years of experience in the development of individual, economical problem solutions. From monofunctional or multifunctional safety relay modules to modular, configurable safety systems with fieldbus connection to radio controlled safety systems, DOLD develops safe, coordinated components from a single source. As a solutions provider, we supply innovative products to a wide variety of markets such as mechanical and plant engineering, power generation and distribution, rail and medical technology, and the raw materials processing industry ... and wherever safety has the highest priority.Everything from a single source - The SAFEMASTER product range includes the following components and systems:

- Emergency stop modules

- Two-hand / safety mat evaluation

- Safety gate monitoring

- Light barrier / light grid evaluation

- Extension / delay / interface modules

- Standstill / speed / frequency monitoring

- Multifunctional safety systems

- Wireless safety solutions.

Benefit from flexible and economical safety solutions for small and medium-sized machines up to large, networked plants. SAFEMASTER products are used worldwide wherever people, machines and plants have to be protected from damage.

Dold Safemaster special devices.

Special devices - Emergency stop monitor, emergency stop device and magnetic switch. The non-contact magnetic switches are suitable for position monitoring of sliding, rotating or removable safety doors as well as in cases of heavy soiling or hygienic requirements. The emergency stop device is used to trigger a switch-off / shutdown of machines and plants in order to avoid danger to persons or damage to the machine and the manufactured products. The emergency stop monitors can be used to monitor the operating status of emergency stop buttons in an emergency stop chain. At the beginning of a machine cycle, a valve monitoring module monitors the position of the valve using a position switch.Solutions from Dold for trouble-free and efficient operation in wastewater treatment plants.

In recent years, the situation in local and industrial wastewater treatment has changed dramatically. In addition to the restoration, modernization and maintenance of wastewater treatment plants, sewage disposal companies today have to face new challenges. For example, the treatment of residues such as microplastics or pharmaceuticals, the reduction of energy consumption, the increase of own power generation by means of block-type thermal power stations or the use of unused potentials (sludge digestion, sewage sludge dewatering etc.). Preventive maintenance measures are also becoming increasingly important. Early fault detection can prevent unplanned failures and thus avoiding time-consuming and costly repairs. This increases the efficiency and availability of the plant and reduces operating costs. The Federal Government also puts new challenges to wastewater treatment plant operators as a result of the new Sewage Sludge Ordinance. In future, many of them will have to recycle sewage sludge instead of spreading it in agriculture. With its products for safe automation, electrical safety and power electronics, DOLD offers a wide range of automation solutions for efficient and resource-saving wastewater treatment.Rely on complete solutions for energy-efficient and safe wastewater treatment in these areas:

- Mechanical pre-treatment

- Secondary sedimentation

- Sludge treatment

- Biological treatment

- Efficient wastewater treatment is essential to protect the environment and water resources.

During mechanical pre-treatment, the solid components contained in the wastewater are retained by a grid and separated by means of a screen and then disposed of.

In the secondary sedimentation in a funnel-shaped tank, the dirt from the sludge-water mixture sediments at the bottom. A clearing device conveys the settled sludge to the top of the hopper, where it is pumped off.

In the biological treatment stage, the finest, non-settleable and most of the dissolved pollutants are removed. The precise control of process variables is a precondition for the optimum cleaning process of the wastewater and the effective operation of the entire wastewater treatment plant.

The solids resulting from wastewater treatment are further treated in the form of sludge. The aim is to process or dispose of this sludge as efficiently as possible.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)