Fuji Electric, ATEX in-situ oxygen analyzers

The oxygen measurement enables the control of burner fuel/air ratios to ensure combustion efficiency and process safety. Fuji Electric O2 Analyzer is adapted to be installed in hazardous areas and to withstand critical environments as:

- Refinery process heaters

- Petrochemical reactor furnaces

- Industrial large scale boilers

The in situ O2 Analyzer includes the following parts :

- 1 probe type ZPF2

- 1 transmitter type ZTF2

- 1 guide tube

- 1 junction box + connection cable if Probe-Transmitter distance >2m

Advantages:

- ATEX/IECEx Zone1 IIB+H2 T3 Gb Probe

- Field-replaceable Flame-arrester

- Compact & Light Design

- Excellent accuracy and reliability

- Remote electronics and calibration.

- Refinery process heaters

- Petrochemical reactor furnaces

- Industrial large scale boilers.

The in situ O2 Analyzer includes the following parts (see typical assembly p.3):

- 1 ZR PROBE type ZPF2

- 1 Remote O2 TRANSMITTER type ZTF2

- 1 Deflecting sampling tube

- 1 Junction box and connection cable if Probe-Transmitter distance >2m

- 1 Calibration kit.

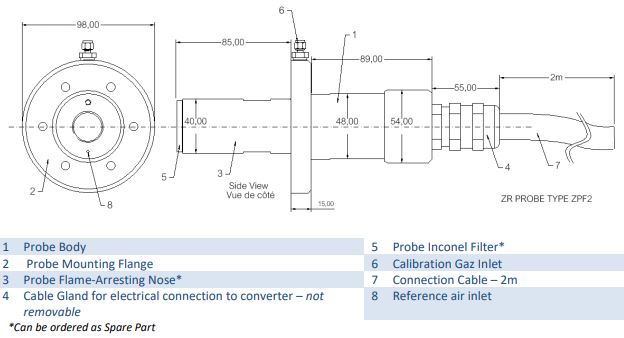

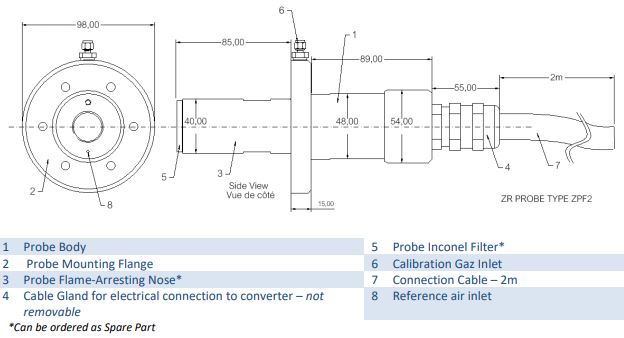

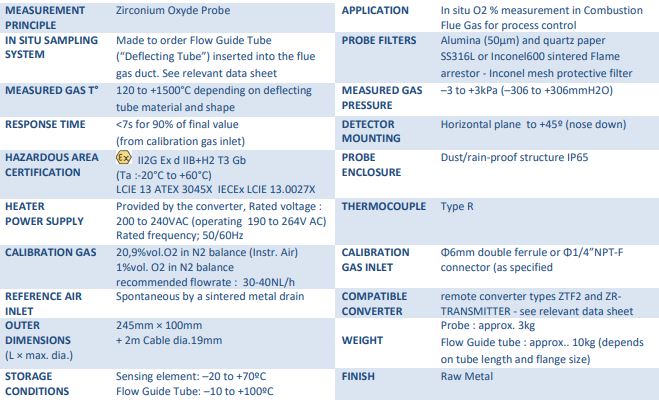

In situ ZR PROBE type ZPF2 is ATEX and IECEx certified to be used in hazardous areas classified up to Zone 1 IIB+H2 T3 Gb, meaning that it complies with the very demanding international standards of exproof security. The ZR PROBE design ensures low maintenance costs and long life-time with excellent accuracy and dependability. It is compact and light (<4kg) to be easily carried for installation and maintenance operations in difficult-to-reach places on site. Its full 316L stainless steel design ensures excellent resistance to saline, humid and corrosive atmospheres over time. The probe features a “flame-arresting nose” which is consumable and replaceable on site. INCONEL600 flame-arrestors are available to improve the probe lifetime with very corrosive applications. In situ sampling is done thanks to a deflecting tube mounted on the flue gas duct mating flange. The tube deflects some of the process flue gas from its main stream and drives it to the probe. This assembly provides fast, highly accurate and reliable measurement while keeping the probe away from the aggressive furnace core. No extractive sampling system is required, avoiding excessive maintenance job typical of ejection pump systems. Also the probe remains easily accessible for maintenance operations.

This flexible sampling technology enables the O2 Analyzer to operate at process temperatures up to 1500°C with highly corrosive or dusty flue gas. Each deflecting tube is designed and made-to-order in order to fit the unit’s specifications (see corresponding data sheet). ZR Probes type ZPF2 are compatible with all RBTechnologies sampling tubes and O2 transmitters already installed. They can efficiently replace worn ZR Probes type ZR PROBE, if ex-proof specifications permit. This compatibility also improves customer stock management. O2 Transmitter type ZTF2 is ATEX certified Zone 1 IIC T6 Gb. It is to be installed remotely from the probe, either on self standing racks at ground level or on wall-mounted panels on platform. This device supplies the power for heating ZR Probes to their operation temperature. Then it turns the sensor’s signal (mV) into O2 (%vol.) concentration. The measured values are displayed on the transmitter’s screen and can be sent to control rooms with 4- 20mA line. Also the electronic converters can provide several helpful functions:

- Analyzer Default Contacts

- Alarm contacts (Very Low, Low, High, Very High)

- Automatic Blow down – Automatic Deflecting tube cleaning with pressured air

- Auto calibration gas sequencer.

Maintenance operations such as calibration and analyzer settings are performed from the transmitter. Calibration gases are sent to the probe from a remote calibration system. Recommended calibration gases are the following:

- 1% O2 in N2 balances - ZERO calibration

- 20.9% O2 in N2 balance - SPAN calibration.

Reference air reaches the sensor through an EXPROOF vent mounted on the probe body. That’s why instrument air is not required for reference.

- Refinery process heaters

- Petrochemical reactor furnaces

- Industrial large scale boilers.

- Refinery process heaters

- Petrochemical reactor furnaces

- Industrial large scale boilers

The in situ O2 Analyzer includes the following parts :

- 1 probe type ZPF2

- 1 transmitter type ZTF2

- 1 guide tube

- 1 junction box + connection cable if Probe-Transmitter distance >2m

Advantages:

- ATEX/IECEx Zone1 IIB+H2 T3 Gb Probe

- Field-replaceable Flame-arrester

- Compact & Light Design

- Excellent accuracy and reliability

- Remote electronics and calibration.

Fuji Electric ANALYZER OVERVIEW.

The oxygen measurement enables the control of burner fuel/air ratios to ensure combustion efficiency and process safety. Fuji Electric O2 Analyzer is adapted to be installed in hazardous areas and to withstand critical environments as:- Refinery process heaters

- Petrochemical reactor furnaces

- Industrial large scale boilers.

The in situ O2 Analyzer includes the following parts (see typical assembly p.3):

- 1 ZR PROBE type ZPF2

- 1 Remote O2 TRANSMITTER type ZTF2

- 1 Deflecting sampling tube

- 1 Junction box and connection cable if Probe-Transmitter distance >2m

- 1 Calibration kit.

In situ ZR PROBE type ZPF2 is ATEX and IECEx certified to be used in hazardous areas classified up to Zone 1 IIB+H2 T3 Gb, meaning that it complies with the very demanding international standards of exproof security. The ZR PROBE design ensures low maintenance costs and long life-time with excellent accuracy and dependability. It is compact and light (<4kg) to be easily carried for installation and maintenance operations in difficult-to-reach places on site. Its full 316L stainless steel design ensures excellent resistance to saline, humid and corrosive atmospheres over time. The probe features a “flame-arresting nose” which is consumable and replaceable on site. INCONEL600 flame-arrestors are available to improve the probe lifetime with very corrosive applications. In situ sampling is done thanks to a deflecting tube mounted on the flue gas duct mating flange. The tube deflects some of the process flue gas from its main stream and drives it to the probe. This assembly provides fast, highly accurate and reliable measurement while keeping the probe away from the aggressive furnace core. No extractive sampling system is required, avoiding excessive maintenance job typical of ejection pump systems. Also the probe remains easily accessible for maintenance operations.

This flexible sampling technology enables the O2 Analyzer to operate at process temperatures up to 1500°C with highly corrosive or dusty flue gas. Each deflecting tube is designed and made-to-order in order to fit the unit’s specifications (see corresponding data sheet). ZR Probes type ZPF2 are compatible with all RBTechnologies sampling tubes and O2 transmitters already installed. They can efficiently replace worn ZR Probes type ZR PROBE, if ex-proof specifications permit. This compatibility also improves customer stock management. O2 Transmitter type ZTF2 is ATEX certified Zone 1 IIC T6 Gb. It is to be installed remotely from the probe, either on self standing racks at ground level or on wall-mounted panels on platform. This device supplies the power for heating ZR Probes to their operation temperature. Then it turns the sensor’s signal (mV) into O2 (%vol.) concentration. The measured values are displayed on the transmitter’s screen and can be sent to control rooms with 4- 20mA line. Also the electronic converters can provide several helpful functions:

- Analyzer Default Contacts

- Alarm contacts (Very Low, Low, High, Very High)

- Automatic Blow down – Automatic Deflecting tube cleaning with pressured air

- Auto calibration gas sequencer.

Maintenance operations such as calibration and analyzer settings are performed from the transmitter. Calibration gases are sent to the probe from a remote calibration system. Recommended calibration gases are the following:

- 1% O2 in N2 balances - ZERO calibration

- 20.9% O2 in N2 balance - SPAN calibration.

Reference air reaches the sensor through an EXPROOF vent mounted on the probe body. That’s why instrument air is not required for reference.

Fuji Electric EX-PROOF IN SITU ZIRCONIUM OXYGEN PROBE FOR COMBUSTION CONTROL SPECIFICATIONS.

The In situ Oxygen Probe ZRPOAR3-200 (Type ZPF2) is an zirconium-oxide oxygen sensor for combustion flue gas analysis. The probe full SS316L design and fieldreplaceable flame-arresting nose provide long life-time and low cost maintenance. For very corrosive applications, probe’s noses made of INCONEL 600 are also available. The probe is light (<4kg) and compact. It is delivered with 2m cable and can be connected to a remote converter at a distance up to 120m thanks to intermediary ex-proof junction box. The ZR PROBE ZRPOAR3-200 is ATEX and IECEx certified to be used in hazardous areas classified up to Zone 1 IIB+H2 T3 Gb, meaning that it has complied to the stringent and very demanding international requirements of security. This device is very adapted for critical applications as :- Refinery process heaters

- Petrochemical reactor furnaces

- Industrial large scale boilers.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)