Fuji Electric FRENIC-Multi (FRN E1) frequency inverter series for general purpose applications

, *Discontinued Series

- Fuji Electric High Performance Compact Inverter

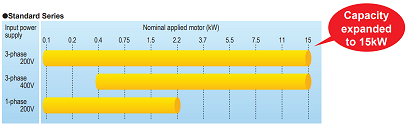

- Availability from 0.1 kW to 15kW

- EMC Filter Buil-tin type (Semi-standard)

- Gentle to the environment

- Simple and thorough maintenance

- Simple operation, simple wiring

- Advanced LCD/LED keypad with clear text description and copy function (3 complete function sets)

| Model | Voltage, V |

Capacity, kW |

Current, A |

V/f mode |

Enclosure IPXX |

Output frequency, Hz |

Overload capacity, % per 1 min |

Dimensions (W x H x D), mm |

Weight, kg |

Price |

|---|---|---|---|---|---|---|---|---|---|---|

| FRN0.1E1S-7E | 200-240 (1ph) | 0,1 | 0.8 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 80х120х112 | 0,6 | on request |

| FRN0.2E1S-7E | 200-240 (1ph) | 0,2 | 1.5 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 80х120х112 | 0,6 | on request |

| FRN0.4E1S-7E | 200-240 (1ph) | 0,4 | 3 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 80х120х127 | 0,7 | on request |

| FRN0.75E1S-7E | 200-240 (1ph) | 0,75 | 5 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 80х120х152 | 0,9 | on request |

| FRN1.5E1S-7E | 200-240 (1ph) | 1,5 | 8 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 110х130х160 | 1,8 | on request |

| FRN2.2E1S-7E | 200-240 (1ph) | 2,2 | 11 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 140х180х151 | 2,4 | on request |

| Model | Voltage, V |

Capacity, kW |

Current, A |

V/f mode |

Enclosure IPXX |

Output frequency, Hz |

Overload capacity, % per 1 min |

Dimensions (W x H x D), mm |

Weight, kg |

Price |

|---|---|---|---|---|---|---|---|---|---|---|

| FRN0.4E1S-4E | 380-480 (3ph) | 0,4 | 1.5 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 110х130х126 | 1,1 | on request |

| FRN0.75E1S-4E | 380-480 (3ph) | 0,75 | 2.5 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 110х130х150 | 1,2 | on request |

| FRN1.5E1S-4E | 380-480 (3ph) | 1,5 | 3.7 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 110х130х150 | 1,7 | on request |

| FRN2.2E1S-4E | 380-480 (3ph) | 2,2 | 5.5 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 110х130х150 | 1,7 | on request |

| FRN4.0E1S-4E | 380-480 (3ph) | 4 | 9 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 140х180х151 | 2,3 | on request |

| FRN5.5E1S-4E | 380-480 (3ph) | 5,5 | 13 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 180х220х158 | 3,4 | on request |

| FRN7.5E1S-4E | 380-480 (3ph) | 7,5 | 18 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 180х220х158 | 3,6 | on request |

| FRN11E1S-4E | 380-480 (3ph) | 11 | 24 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 220х260х195 | 6,1 | on request |

| FRN15E1S-4E | 380-480 (3ph) | 15 | 30 | + | IP 20 | 25-400 | 150% / 1 min; 200% / 0.5 sec | 220х260х195 | 7,1 | on request |

Fuji Electric vfd FRENIC-Multi is gentle on the environment

- Complies with European regulations that limit the use of specific hazardous substances (RoHS)These inverters are gentle on the environment. Use of 6 hazardous substances is limited (except for interior soldering in the power module.)

- Long-life design

The design life of each internal component with limited life has been extended to 10 years. This helps to extend the maintenance cycle for your equipment.

- Noise is reduced by the built-in EMC filter

Use of a built-in EMC filter that reduces noise generated by the inverter makes it possible to reduce the effect on peripheral equipment.

Expanded capacity range and abundant model variation for Fuji Electric drive FRENIC-Multi series

Semi-Standard type:

- EMC filter built-in type

Option card:

- PG interface card (5V type)(12V type)

- RS-485 communication card

- Synchronized operation card

- Device Net card

- Profibus-DP card

- DIO card

- CC-Link card

Fuji Electric inverter FRENIC-Multi has the highest standards of control and performance in its class

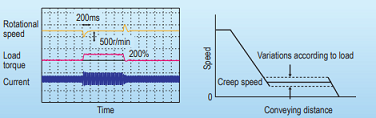

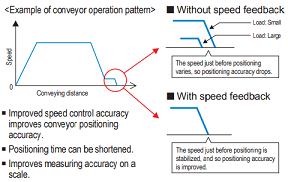

Through "slip compensation control" + "voltage tuning," speed control accuracy at low speeds is improved. This minimizes variations in speed control accuracy at times when the load varies, and since the time at creep speeds is shortened, single cycle tact times can be shortened.

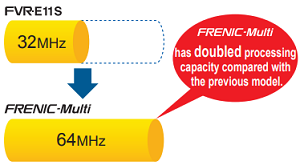

The highest level CPU of any inverter is used. Computation and processing capacity is doubled over the previous inverter, improving speed control accuracy.

Compatible with PG feedback control

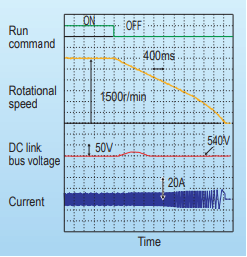

The inverter controls the energy level generated and the deceleration time, and so deceleration stop can be accomplished without tripping due to overvoltage.

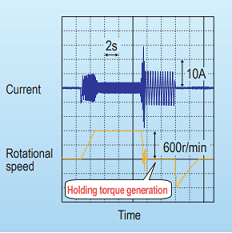

Optimum for the operations specific to vertical and horizontal conveyance

Impacts are detected mechanically and not only can the inverter's operation pattern be set on coast-to-stop or deceleration stop, but switching from torque limitation to current limitation and generating a holding torque (hit-andstop control) can be selected, making it easy to adjust brake application and release timing.

- At brake release time

After the motor operates, torque generation is detected and signals are output.

- At brake application time

Brake application that matches the timing can be done, and so mechanical brake wear is reduced.

Limit operations can be selected to match your equipment

Inverters are equipped with two limit operations, "torque limitation" and "current limitation," so either can be selected to match the equipment you are using the inverter with.

- Torque limitation In order to protect mechanical systems, this function accurately limits the torque generated by the motor. (Instantaneous torque cannot be limited.)

- Current limitation This function limits the current flowing to the motor to protect the motor thermally or to provide rough load limitation. (Instantaneous current cannot be limited. Auto tuning is not required.)

Fuji Electric drive FRENIC-Multi has a Simple and thorough maintenance

The life information on each of the inverter's limited life components is displayed.

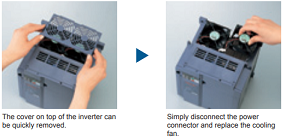

Simple cooling fan replacement:

Construction is simple, enabling quick removal of the top cover and making it easy to replace the cooling fan. (7.5HP or higher models)

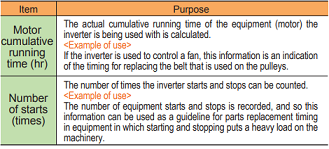

Information that contributes to equipment maintenance is displayed:

In addition to inverter maintenance information, data that also take equipment maintenance into consideration are displayed.

Fuji Electric drive FRENIC-Multi series is easy to operate, simple to connect

- A removable keypad is standard equipment.

The keypad can be easily removed and reset, making remote operation possible. If the back cover packed with the inverter is installed and a LAN cable is used, the keypad can be easily mounted on the equipment's control panel.

- A removable interface card is adapted.

Wiring is quite easy because the interface card can be attached and detached as a terminal base for control signals.

- A multi-function keypad which enables a wide variety of operations is available.

A multi-function keypad is available as an option. This keypad features a large 7-segment LED with five digits and large back-lighted liquid crystal panel. Its view-ability is high, and guidance is displayed on the liquid crystal panel, therefore operations can be conducted simply. (A copy function is included.)

- Inverter support loader software is available.

Windows compatible loader software is available to simplify the setting and management of function codes.

- Simulated failure enables peripheral device operation checks.

The inverter has the function for outputting dummy alarm signals, enabling simple checking of sequence operations of peripheral devices from the control panel where the inverter is used.

Consideration of peripheral equipment, and a full range of protective functions

-Side-by-side mounting saves space.

If your control panel is designed to use multiple inverters, these inverters make it possible to save space through their horizontal side-by-side installation. (5HP or smaller models)

- Resistors for suppressing inrush current are built in, making it possible to reduce the capacity of peripheral equipment.

When FRENIC-Multi Series (including FRENIC-Mini Series, FRENIC-Eco Series and 11 Series) is used, the built-in resistor suppresses the inrush current generated when the motor starts. Therefore, it is possible to select peripheral equipment with lower capacity when designing your system than the equipment needed for direct connection to the motor.

- Outside panel cooling is also made possible using the mounting adapter for external cooling (option).

The mounting adapter for external cooling (option) can be installed easily as an outside panel cooling system.

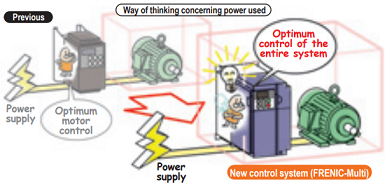

Fuji Electric inverter FRENIC-Multi series can be used equipped with functions like these

- New system for more energy-efficient operation.

Previous energy saving operation functions worked only to control the motor's loss to keep it at a minimum in accordance with the load condition. In the newly developed FRENIC-Multi Series, the focus has been switched away from the motor alone to both the motor and the inverter as electrical products. As a result, we incorporated a new control system (optimum and minimum power control) that minimizes the power consumed by the inverter itself (inverter loss) and the loss of the motor.

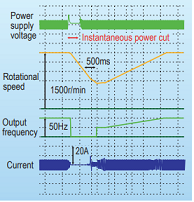

- Smooth starts through the pick-up function

In the case where a fan is not being run by the inverter but is turning free, the fan's speed is checked, regardless of its rotational direction, and operation of the fan is picked up to start the fan smoothly. This function is convenient in such cases as when switching instantaneously from commercial power supply to the inverter.

- Equipped with a full range of PID control functions.

Differential alarm and absolute value alarm outputs have been added for PID adjusters which carry out process controls such as temperature, pressure and flow volume control. In addition, an anti-reset windup function to prevent PID control overshoot and other PID control functions which can be adjusted easily through PID output limiter, integral hold/reset signals are provided. The PID output limiter and integral hold/reset signals can also be used in cases where the inverter is used for dancer control.

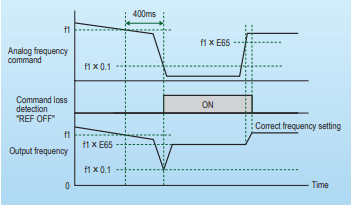

- Operating signal trouble is avoided by the command loss detection function.

If frequency signals connected to the inverter (0 to 10V, 4 to 20mA, Multi-speed signals, communications, etc.) are interrupted, the missing frequency commands are detected as a "command loss." Further, the frequency that is output when command loss occurs can be set in advance, so operation can be continued even in cases where the frequency signal lines are cut due to mechanical vibrations of the equipment, etc.

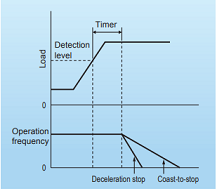

- An overload stop function protects equipment from over-operation.

If the load on equipment suddenly becomes great while controlled by the inverter, the inverter can be switched to deceleration stop or to coast-to-stop operation to prevent damage to the equipment.

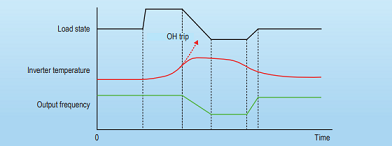

- Continuous equipment operation with overload avoidance control.

If foreign matter gets wrapped around a fan or pulley and the load increases, resulting in a sudden temperature rise in the inverter or an abnormal rise in the ambient temperature, etc. and the inverter becomes overloaded, it reduces the motor's speed, reducing the load and continuing operation.

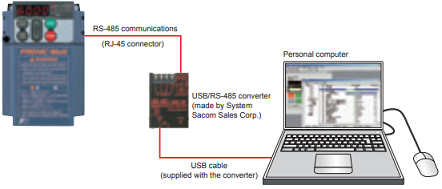

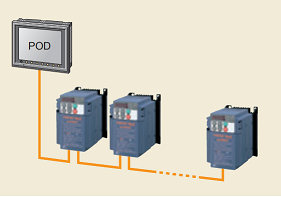

Fuji Electric inverter FRENIC-Multi series is fully compatible with network operation

- RS-485 communications (connector) is standard.

A connector (RJ-45) that is compatible with RS-485 communications is standard equipment (1 port, also used for keypad communications), so the inverter can be connected easily using a LAN cable (10BASE).

- Complies with optional networks using option cards.

Installation of special interface cards (option) makes it possible to connect to the following networks.

- Wiring is easy with the RS-485 communications card (optional).

The RS-485 communications card is also available as an option. When it is installed, you can add a branch connection that is separate from the communications port provided as standard equipment (RJ-45 connector), and have two communications ports.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)