Fuji Electric FRENIC-AQUA (FRN AQ1) frequency inverter series for pumps and water supply

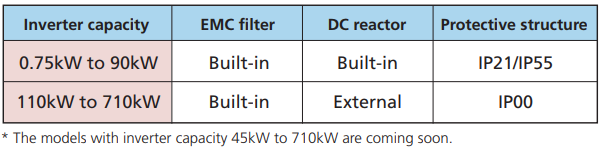

- Wide capacity range from 0.75 kW to 710 kW

- IP21 & IP55 with same dimension

- Up to 90 kW with integrated DC link reactor and EMC filter. Integrated EMC filter for all capacities

- Overload capability 110%

- User-defined logic (mini PLC), 14 steps, digital and analog signals possible

- Modbus RTU, BACnet MS/TP and Metasys N2 integrated as standard

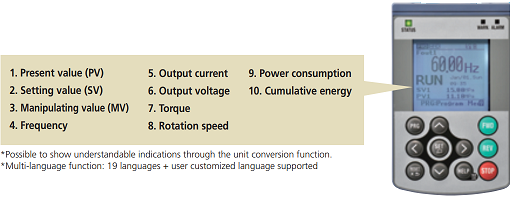

- Large LCD display, 19 languages and user-defined language

- Torque vector control

- Real Time Clock (RTC)

- Standard 4 PID control

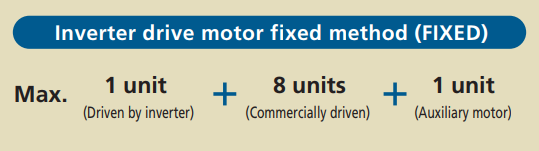

- Multipump control (up to 9 pumps with one inverter)

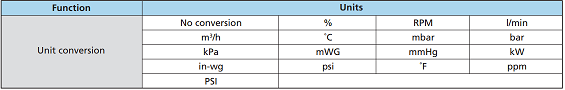

- Unit conversion function (kPa, bar, l/min, etc.)

- Emergency operation (forced running)

- Interception of a freely rotating motor

- New energy-saving functions (sleep mode)

- Extension cable for remote control CB – S

- Pipe fill mode

- Anti-jam function

| Model | Voltage, V |

Capacity, kW |

Current, A |

V/f mode |

Enclosure IPXX |

Output frequency, Hz |

Overload capacity, % per 1 min |

Dimensions (W x H x D), mm |

Weight, kg |

Price |

|---|---|---|---|---|---|---|---|---|---|---|

| FRN0.75AQ1M-4E | 380~480 (3ph) | 0,75 | 2.5 | + | IP 21 | 25-120 | 110 | 150x465x262 | 10 | € 367,00 |

| FRN1.5AQ1M-4E | 380~480 (3ph) | 1,5 | 4.1 | + | IP 21 | 25-120 | 110 | 150x465x262 | 10 | € 431,00 |

| FRN2.2AQ1M-4E | 380~480 (3ph) | 2,2 | 5.5 | + | IP 21 | 25-120 | 110 | 150x465x262 | 10 | € 459,00 |

| FRN4.0AQ1M-4E | 380~480 (3ph) | 4 | 9 | + | IP 21 | 25-120 | 110 | 150x465x262 | 10 | € 590,00 |

| FRN5.5AQ1M-4E | 380~480 (3ph) | 5,5 | 13.5 | + | IP 21 | 25-120 | 110 | 150x465x262 | 10 | € 663,00 |

| FRN7.5AQ1M-4E | 380~480 (3ph) | 7,5 | 18.5 | + | IP 21 | 25-120 | 110 | 150x465x262 | 10 | € 822,00 |

| FRN11AQ1M-4E | 380~480 (3ph) | 11 | 24.5 | + | IP 21 | 25-120 | 110 | 203x585x262 | 18 | € 983,00 |

| FRN15AQ1M-4E | 380~480 (3ph) | 15 | 32 | + | IP 21 | 25-120 | 110 | 203x585x262 | 18 | € 1 215,00 |

| FRN18.5AQ1M-4E | 380~480 (3ph) | 18,5 | 39 | + | IP 21 | 25-120 | 110 | 203x585x262 | 18 | € 1 361,00 |

| FRN22AQ1M-4E | 380~480 (3ph) | 22 | 45 | + | IP 21 | 25-120 | 110 | 203x585x262 | 18 | € 1 625,00 |

| FRN30AQ1M-4E | 380~480 (3ph) | 30 | 60 | + | IP 21 | 25-120 | 110 | 203x645x262 | 23 | € 1 860,00 |

| FRN37AQ1M-4E | 380~480 (3ph) | 37 | 75 | + | IP 21 | 25-120 | 110 | 203x645x262 | 23 | € 2 320,00 |

| FRN45AQ1M-4E | 380~480 (3ph) | 45 | 91 | + | IP21 | 25-120 | 110 | - | - | € 2 825,00 |

| FRN55AQ1M-4E | 380~480 (3ph) | 55 | 112 | + | IP21 | 25-120 | 110 | - | - | € 3 378,00 |

| FRN75AQ1M-4E | 380~480 (3ph) | 75 | 150 | + | IP21 | 25-120 | 110 | - | - | € 3 987,00 |

| FRN90AQ1M-4E | 380-480 (3ph) | 90 | 176 | + | IP21 | 25-120 | 110 | - | - | € 4 552,00 |

| Model | Voltage, V |

Capacity, kW |

Current, A |

V/f mode |

Enclosure IPXX |

Output frequency, Hz |

Overload capacity, % per 1 min |

Dimensions (W x H x D), mm |

Weight, kg |

Price |

|---|---|---|---|---|---|---|---|---|---|---|

| FRN0.75AQ1L-4E | 380~480 (3ph) | 0,75 | 2.5 | + | IP 55 | 25-120 | 110 | 150x465x262 | 10 | € 432,00 |

| FRN1.5AQ1L-4E | 380~480 (3ph) | 1,5 | 4.1 | + | IP 55 | 25-120 | 110 | 150x465x262 | 10 | € 509,00 |

| FRN2.2AQ1L-4E | 380~480 (3ph) | 2,2 | 5.5 | + | IP 55 | 25-120 | 110 | 150x465x262 | 10 | € 559,00 |

| FRN4.0AQ1L-4E | 380~480 (3ph) | 4 | 9 | + | IP 55 | 25-120 | 110 | 150x465x262 | 10 | € 669,00 |

| FRN5.5AQ1L-4E | 380~480 (3ph) | 5,5 | 13.5 | + | IP 55 | 25-120 | 110 | 150x465x262 | 10 | € 739,00 |

| FRN7.5AQ1L-4E | 380~480 (3ph) | 7,5 | 18.5 | + | IP 55 | 25-120 | 110 | 150x465x262 | 10 | € 892,00 |

| FRN11AQ1L-4E | 380~480 (3ph) | 11 | 24.5 | + | IP 55 | 25-120 | 110 | 203x585x262 | 18 | € 1 056,00 |

| FRN15AQ1L-4E | 380~480 (3ph) | 15 | 32 | + | IP 20 | 25-120 | 110 | 203x585x262 | 18 | € 1 264,00 |

| FRN18.5AQ1L-4E | 380~480 (3ph) | 18,5 | 39 | + | IP 55 | 25-120 | 110 | 203x585x262 | 18 | € 1 492,00 |

| FRN22AQ1L-4E | 380~480 (3ph) | 22 | 45 | + | IP 55 | 25-120 | 110 | 203x585x262 | 18 | € 1 755,00 |

| FRN30AQ1L-4E | 380~480 (3ph) | 30 | 60 | + | IP 55 | 25-120 | 110 | 203x645x262 | 23 | € 2 070,00 |

| FRN37AQ1L-4E | 380~480 (3ph) | 37 | 75 | + | IP 55 | 25-120 | 110 | 203x645x262 | 23 | € 2 512,00 |

| FRN45AQ1L-4E | 380-480 (3ph) | 45 | 91 | + | IP55 | 25-120 | 110 | - | - | € 3 017,00 |

| FRN55AQ1L-4E | 380-480 (3ph) | 55 | 112 | + | IP55 | 25-120 | 110 | - | - | € 3 561,00 |

| FRN75AQ1L-4E | 380-480 (3ph) | 75 | 150 | + | IP55 | 25-120 | 110 | - | - | € 4 193,00 |

| FRN90AQ1L-4E | 380-480 (3ph) | 90 | 176 | + | IP55 | 25-120 | 110 | - | - | € 4 770,00 |

| Model | Voltage, V |

Capacity, kW |

Current, A |

V/f mode |

Enclosure IPXX |

Output frequency, Hz |

Overload capacity, % per 1 min |

Dimensions (W x H x D), mm |

Weight, kg |

Price |

|---|---|---|---|---|---|---|---|---|---|---|

| FRN110AQ1S-4E | 380-480 (3ph) | 110 | 210 | + | IP00 | 25-120 | 110 | - | - | € 5 409,00 |

| FRN132AQ1S-4E | 380-480 (3ph) | 132 | 253 | + | IP00 | 25-120 | 110 | - | - | € 6 837,00 |

| FRN160AQ1S-4E | 380-480 (3ph) | 160 | 304 | + | IP00 | 25-120 | 110 | - | - | € 8 205,00 |

| FRN200AQ1S-4E | 380-480 (3ph) | 200 | 377 | + | IP00 | 25-120 | 110 | - | - | € 10 297,00 |

| FRN220AQ1S-4E | 380-480 (3ph) | 220 | 415 | + | IP00 | 25-120 | 110 | - | - | € 11 709,00 |

| FRN280AQ1S-4E | 380-480 (3ph) | 280 | 520 | + | IP00 | 25-120 | 110 | - | - | € 14 225,00 |

| FRN315AQ1S-4E | 380-480 (3ph) | 315 | 585 | + | IP00 | 25-120 | 110 | - | - | € 16 386,00 |

| FRN355AQ1S-4E | 380-480 (3ph) | 355 | 650 | + | IP00 | 25-120 | 110 | - | - | € 18 459,00 |

| FRN400AQ1S-4E | 380-480 (3ph) | 400 | 740 | + | IP00 | 25-120 | 110 | - | - | € 21 324,00 |

| FRN500AQ1S-4E | 380-480 (3ph) | 500 | 960 | + | IP00 | 25-120 | 110 | - | - | € 23 940,00 |

| FRN630AQ1S-4E | 380-480 (3ph) | 630 | 1170 | + | IP00 | 25-120 | 110 | - | - | € 29 078,00 |

| FRN710AQ1S-4E | 380-480 (3ph) | 710 | 1370 | + | IP00 | 25-120 | 110 | - | - | € 32 076,00 |

Wide variation of model capacity in FRENIC-Aqua frequency inverter series

Model can be selected from two model types:

- Standard type (EMC filter built-in type) 0.75~710kW (Protective structure IP21 or IP55 can be selected between 0.75 and 90kW)

- DCR built-in + EMC filter built-in type 0.75~90kW (Protective structure IP21 or IP55 can be selected between 0.75 and 90kW)

Fuji inverter Frenic-Aqua series has a control terminal block

Fuji frequency inverter Frenic-Aqua series has a capacitor board

Fuji drive Frenic-Agua series has a cooling fan

Easy replacement just by simply removing and attaching the part. Life prolongation is possible by controlling ON and OFF

Fuji Electric vfd Frenic-Aqua series has a EMC-filter

Drastically reduces noise. Provided to units of all capacities. Conforming to IEC61800-3.

Fuji Electric drive Frenic-Aqua series has a DCR

Drastically reduces harmonic noise. Conforming to IEC/EN61000-3-2 and IEC/EN61000-3-12. Provided as standard (to models up to 90kW), and can be attached externally as an option (to models from 110kW to 710kW).Fuji FRENIC-Aqua inverter with optimum control by energy-saving functions

- Linearization function- Temperature difference constant control and pressure difference constant control

- Energy saving functions including wet-bulb temperature presumption control

- Automatic energy-saving operation

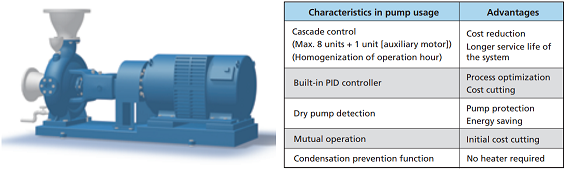

Dedicated pump control function provided as standard

- 4PID control

- Cascade control

- Mutual operation

- Control of maximum starts per hour

- Dry pump detection

- Deceleration time for check valve protection

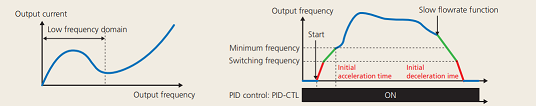

- Slow flowrate function

- End of curve detection

- Boost function

- Acceleration and deceleration at initial stage

Slim body

The first slim body design among the Fuji Electric inverters. The size is the same between IP21 and IP55 (the first in the industry).Fuji Electric FRENIC-Aqua drives are user-friendly and with useful functions

- Fire Mode (forced operation)- Customized logic

- Pick-up operation function

- Anti-jam

- Torque vector control

- Password function

- Real time clock

- User friendly, useful key pad

Stand alone

The inverter can be installed independently; no control panel is required.

Wide usage of Fuji Electric FRENIC-Aqua inverter for Water Treatment

Irrigation system

Seawater desalination

Fuji Electric drives FRENIC-Aqua series pump control features

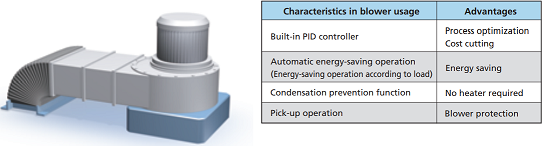

Fuji Electric drives FRENIC-Aqua series blower control features

FRENIC-Aqua series is equipped with many functions that control the pumps and blowers used in water treatment facility optimally.

Fluid-pressure device

- Oil pumping system

- Injection machine

- Hydraulic press machine

- Extruders

- Cold and Air Compressors

User friendly, easy to see keypad

The regulator is indicated by enlarging the LCD.

Fuji Electric vfd Frenic-Aqua series is supported by multi-language: 19 languages + user customized language (Planned)

Fuji Electric's real time clock (RTC) is provided as standard.

- Alarm information with date and time: Alarm information for last ten times is stored and displayed with date and time- Timer function: 1) Possible to set the maximum four timers for a week. 2) Possible to set flag holidays (20 days a year).

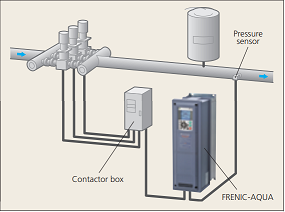

- Unit conversion function between PV and SV values: Unit conversion allows you to easily set data

The cascade control is the function that controls the multiple pumps by one inverter. The pumps are controlled with combination of inverter drive and commercial drive. This can be applied in a large-scale water treatment plant. In cascade control, the signals of flow rate and pressure sensors are controlled by the PID regulator that is built in the inverter. Each pump is driven either by the inverter or commercially according to the switching signal from the inverter. The pumps are controlled only by the inverter when the discharge volume is small, and adding to the inverter drive, they are controlled using commercial drive by adding them one by one as the discharge volume gets larger in order to ensure the required discharge volume in total. There are two following methods in control: inverter drive motor fixed method and inverter drive motor fixed method.

The system is configured by combining the motor driven by the inverter (M0), motors that are commercially driven (M1 to M8) and auxiliary motor (MA). TThe motor driven by the inverter is always fixed as motor M0. Motors commercially driven are added one by one in control when the required discharge flow rate cannot be achieved with the motor M0 only.

- Mutual operation

The system can be configured without using a controller by connecting the inverters via communications. In this system, if a failure occurs to the master inverter, the next inverter is driven as the master inverter. Moreover, wiring can be saved with use of communications services, which eliminates the need of additional options by using the Modbus RTU communications.

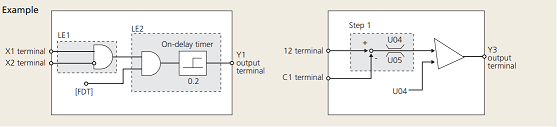

Customized logic

The customized logic interface function is provided to the inverter body. This enables forming of logic circuit and arithmetic circuit to the digital and analog input and output signals, allowing simple relay sequence to be built while processing the signals freely.

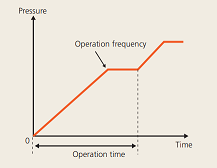

Boost function

Frequency can be output forcibly at a fixed rate in preference to PID control. By setting the operation frequency, operation time, and acceleration time at starting, optimal operation for starting the pump can be achieved.Pressurizing operation can be applied for a certain period of time at the time of start.

Password

Dry pump detection

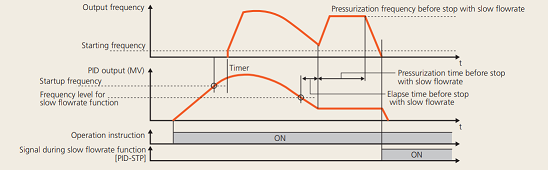

Slow flowrate function (pressurized operation available before slow flowrate)

The inverter can be stopped when the discharge rate becomes low due to increase of pump discharge pressure. Facility having a bladder tank can make the stoppage period longer by applying pressure immediately before stoppage, which realizes energy-saving operation.

Initial acceleration/deceleration time

When a pump such as a deep well pump is operated at low speed over a long period of time, the pump may be damaged since the load current is large in the low-speed range. It is possible to provide acceleration/deceleration time specific to the low-speed range in order to avoid prolonged operation.

Anti-jam function

The motor is rotated in reverse when it is determined that any abnormality, such as being engaged or trapped, is occurred. If sand or dust were caught in the impeller with a submerged pump and overcurrent protection function is activated, the motor is rotated in reverse at restart so that the sand and dust are ejected from the impeller. Then, the motor resumes rotation in forward, allowing water to be supplied in a normal manner.

Deceleration time for check valve protection

If a valve is closed quickly after pump stoppage, there is a risk of damaging the check valve (piping, pump, valves, etc.) due to water hammer phenomenon. To protect the check valve from this, the pump speed is gradually slowed down when the check valve closes.Other Fuji vfd Frenic-Aqua series featured functions

- 4PID control- Control of maximum starts per hour

- Abnormal pressure rise prevention

- End of curve detection

- Pick-up operation

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)