DOLD Multifunctional Radio controlled safety modules: SAFEMASTER W

Sometimes, people must enter into the hazardous areas of running machines or systems in order to calibrate the machine or remedy a problem. The wireless enable switch SAFEMASTER W is the ideal companion for your safety in such situations. It switches off any dangerous movements in just a fraction of a second. SAFEMASTER W consists of a lightweight, ultra-compact hand-held transmitter and a radio safety switch with safety-oriented outputs. The signal transmission via radio and/or infra-red ensures that only systems in the field of vision of the hand-held transmitter can be activated.

| Type | Function | Application | Category acc. to EN 13849-1 * | Safe output contact | Auxiliary | Solid state output not safe (radio) | Width [mm] | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Emergency-stop | Light curtain | Safety gate | Start | Wireless | NC contact | Feedback for ext. monitoring | ||||||

| BI 5910 | Radio controlled safety module | + | + | + | + | + | 4 / e | 3 | 1 | 1 | 6 | 67.5 |

| BI 6910 | Radio controlled safety module | + | + | + | + | + | 4 / e | 4 | 1 | 1 | 6 | 67.5 |

* Please check state of approval of idividual devices in the latest data sheet.

For more complex applications see SAFEMASTER with Wireless

For more complex applications see SAFEMASTER with Wireless

DOLD Remote control SAFEMASTER W

| Type | Function | Emergency-stop pushbutton | Start button | 1-step push buttons BPSV | 2-step push buttons | Rotational switch COM3 | Rotational switch with auto return COM3R | Infrared | Personal safety key | Marking areas | Measures [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RE 5910/001 | Remote control for BI 5910 | + | + |

|

4 |

|

|

|

+ | 4 | 46 x 73 x 143 |

| RE 5910/002 | Remote control for BI 5910 | + | + |

|

4 |

|

|

+ | + | 4 | 46 x 73 x 143 |

| RE 5910/003 | Remote control for BI 5910 | + | + | 4 |

|

|

|

|

+ | 4 | 46 x 73 x 143 |

| RE 5910/004 | Remote control for BI 5910 | + | + | 4 |

|

|

|

+ | + | 4 | 46 x 73 x 143 |

| RE 5910/005 | Remote control for BI 5910 | + | + | 3 |

|

|

1 |

|

+ | 4 | 46 x 73 x 143 |

| RE 5910/006 | Remote control for BI 5910 | + | + | 2 |

|

2 |

|

+ | + | 4 | 46 x 73 x 143 |

| RE 5910/007 | Remote control for BI 5910 | + | + | 2 |

|

2 |

|

|

+ | 4 | 46 x 73 x 143 |

| RE 6910/001 | Remote controlled enabling switch for BI 6910 | + |

|

|

|

|

|

|

|

|

46 x 73 x 143 |

DOLD Accessories for SAFEMASTER W

| Type | Accessories for: | Description |

|---|---|---|

| RE 5910/010 |

Remote control BI 5910 |

Industrial charger unit |

| RE 5910/011 | Power supply for charger AC 230V (Euro connector) | |

| RE 5910/013 | Power supply for charger AC 230V (U.K. connector) | |

| RE 5910/012 | Power supply for charger DC 24 V | |

| RE 5910/020 * | Green electronic key with program | |

| RE 5910/021 * | Orange electronic key with program | |

| RE 5910/030 | Set with 6 colour stickers “movements” for 2-step push buttons | |

| RE 5910/031 | Set with 90 black and white stickers | |

| RE 5910/033 | Set with 48 white stickers + 48 transparent protection stickers for individual marking | |

| RE 5910/051 | Replacement rechargeable battery | |

| RE 5910/070 | Remote control holster for RE5910; Material: leather, - metal clip to fix it on belt. - with rings to clip in the personal mounting harness RE 5910/071 | |

| RE 5910/071 | Personal mounting harness with elastic straps to carry the remote control in the holster RE 5910/070 on the body of the operator. | |

| RE 6910/010 |

Radio controlled enabling switch BI 6910 |

Industrial charger unit |

| RE 6910/020 | Replacement SIM-Card | |

| RE 6910/051 | Replacement rechargeable battery | |

| RE 6910/070 | Remote control holster for RE5910; Material: leather, - metal clip to fix it on belt. | |

| RE 5910/040 |

Radio controlled safety module RE 5910 |

Straight 1/4 l aerial 433-434 MHZ – BNC |

| RE 5910/041 | Straight 1/2 l aerial 433-434 MHZ – BNC | |

| RE 5910/042 | 2 m Extension for aerial + trough hole connector – BNC + fixing angle | |

| RE 5910/043 | 5 m Extension for aerial + trough hole connector – BNC + fixing angle | |

| RE 5910/045 | Extension 50 cm + trough hole connecto | |

| RE5910/044 | Aerial link with 2 aerials RE5910/040 and 5 m wire | |

| RE 5910/046 | 90° adapter for aerial | |

| RE 5910/060 | 1 infra red receiver with 10 m wire | |

| RE 5910/061 | 10 m extension wire for infra red module | |

| RE 6910/001 |

Radio controlled safety module RE 6910 |

Enabling switch 1 mW 64 channels |

| RE 6910/002 | Enabling switch 10 mW 25 channels | |

| RE 5910/040 | Straight 1/4 l aerial 433-434 MHZ – BNC | |

| RE 5910/041 | Straight 1/2 l aerial 433-434 MHZ – BNC | |

| RE 5910/042 | 2 m Extension for aerial + trough hole connector – BNC + fixing angle | |

| RE 5910/043 | 5 m Extension for aerial + trough hole connector – BNC + fixing angle | |

| RE 5910/045 | Extension 50 cm + trough hole connecto | |

| RE 5910/046 | 90° adapter for aerial | |

| RE 5910/060 | 1 infra red receiver with 10 m wire | |

| RE 5910/061 | 10 m extension wire for infra red module |

* Important: Please state the following details on order:

- Number of electronic key (6 figure number, noted on page 2 of this manual)

- Frequency channel, if it should be programmed by manufacturer

- Time delay for activity control (01-99 sec or 01-98 min)

The UH 6900 wireless safety system offers new options and solutions in the field of functional safety. Even in areas where classic safety technology has confronted its limitations:

- If you need to securely activate an emergency disconnect for systems wirelessly in a far-away high-bay shelving unit,

- Ensure safe access to hazardous areas with continuously running machines or conveyor belts

- Or whether you need to safely stop a system to complete maintenance work on a conveyor belt or other moving equipment.

It’s no problem with UH 6900 wireless safety modules! Safe certified radio controlled technology by DOLD offers a wide variety of combinations for autonomous, mobile and stationary systems.

Wireless, safe, reliable.

The new UH 6900 is part of the SAFEMASTER W series of wireless safety systems. it offers safety-oriented, bidirectional transmission of E-stop and control functions offering greater flexibility for the protection of hazardous areas up to Cat. 4 / PL e or SIL 3. By implementing the latest radio-controlled technologies, a high degree of plant availability and safety is achieved. Two safety zones can be connected wirelessly to each other over a considerable distance. The main application areas include wide ranging systems and mobile applications such as fully automated conveyor systems and driverless autonomous transport systems.

Easy set-up procedure, configurable modules.

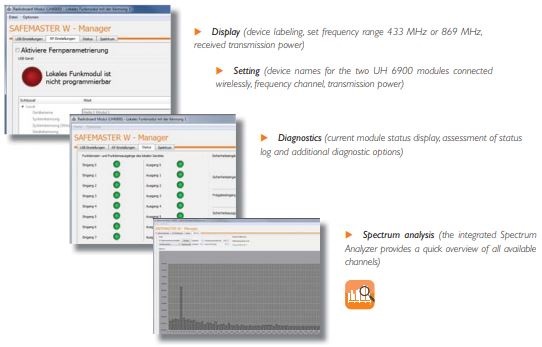

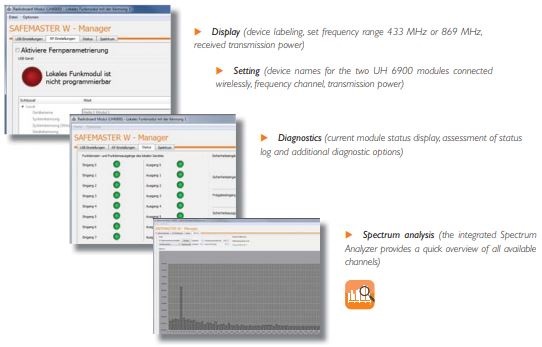

Quick set-up is possible thanks to pre-configured modules. The free SAFEMASTER W Manager software makes it easy to adapt the modules for different functions. Additional diagnostic functions aid set up in the field.

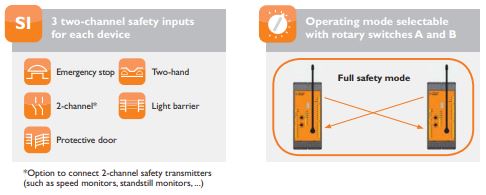

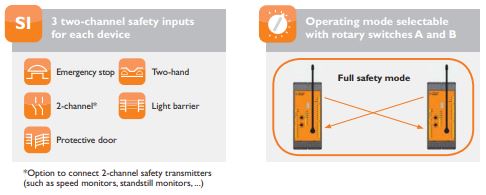

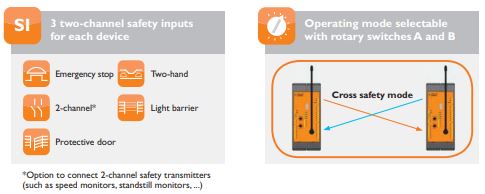

The TÜV certified UH 6900 wireless safety module is suitable for safety requirements up to Cat. 4 / PL e or SIL 3. The safety modules each have 3 two-channel safety inputs (such as emergency stop, light curtain, safety gate, etc.) and 1 safety output with 3 redundant contact paths. In addition, the modules each provide 8 inputs and outputs for user-specific control functions. Two additional status semi-conductor outputs, one indicator output for reception quality, and the USB interface provide for comprehensive diagnostic options.

Operating modes / Start options.

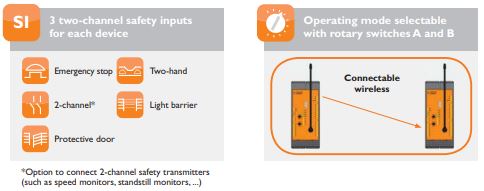

Safe operating modes, selectable system start – simple and functional. The following operating modes can be selected using the rotary switches: Full safety mode, cross safety mode, and safety mode with selectable optional radio control. This allows you to quickly adapt the system to your safety application. In addition, automatic, manual, or two-hand start options are available for system start.

Safe, wireless emergency stop – safely separate system components and zones. Just two UH 6900 wireless safety modules are required to fully secure two hazardous zones. Both wireless safety modules are connected by a bidirectional safe radio connection. If a safety function is triggered (such as emergency stop, safety gate, etc.), both UH 6900 wireless safety modules shut down the entire system in both hazardous areas in a safe controlled manner.

Application example - Full safety mode:

If a safety function (emergency stop or safety gate) is activated on a system in zone 1 or zone 2, both systems are powered down in a safe and controlled manner. Only after they are shut down can persons enter the hazardous area (for instance access through releasing a safety gate lock (SAFEMASTER STS)).

Safe, wireless protection for hazardous areas, monitoring to multiple conditions. Even complicated tasks can be handled easily with just two wireless safety modules. A safe function (access approval, start a subsequent process, etc.) is only wirelessly released if a condition, for instance in zone 1, is fulfilled. Only then is a safety function (such as access authorisation) triggered wirelessly from the other safety zone. An example: A conveyor belt in a hazardous area first has to be run in no-load operation and the belt stopped before safety gates can be released to allow access. In this operating mode, the system ensures that persons can only enter a hazardous area if the equipment or system is safe.

Application example - Cross safety mode:

A person wants to enter a secure system area (zone 2). The person activates the emergency stop in zone 1. The emergency stop signal from zone 1 is transmitted wirelessly to zone 2. The machine in zone 2 powers down in a controlled manner. As soon as it reaches a safe status, it returns a release signal for zone 2 (for instance, approve safety gate locking). Only then can the person safely enter zone 2.

Link safety and control functions. A UH 6900 wireless safety module monitors a production system in a hazardous area. The device first works locally without a wireless connection with its safety inputs and output. However, there is the option to connect a second UH 6900 wireless safety module (e. g. in a forklift) to the safety functions (such as emergency stop) in the production system and safely drive through the hazardous area (additional authentication can be provided by an optional infrared connection). When the wireless connection between the two modules is created, the safety functions of both devices will be active. In a hazardous situation, both the forklift and or the machine can trigger an emergency stop.. In addition, certain control functions of the system (such as the crane) can be used – entirely safely and without additional wiring work.

Application example - Safety mode with wireless connection option:

A wireless safety module secures a production system in zone 2. It first works fully autonomously without a wireless connection. A second wireless safety module is located in the forklift. To pick up produced parts on pallets, the forklift (zone 1) has to drive into the system. In order to gain access to the system (zone 2), the forklift must connect wirelessly and position itself in the specified start zone (green) and authenticate itself via infrared connection. Access to the hazardous area is approved and the forklift can drive into zone 2. The safety functions (such as emergency stop) of both modules are now active, defined control functions can be activated by the mobile vehicle. In a hazardous situation, both the forklift and the machine operator can trigger an emergency stop. Your advantage: Access to approved control functions for the loading crane and mobility and safety in the system‘s hazardous area.

- Number of electronic key (6 figure number, noted on page 2 of this manual)

- Frequency channel, if it should be programmed by manufacturer

- Time delay for activity control (01-99 sec or 01-98 min)

Technical Information and Features

DOLD SAFEMASTER W – Wireless Safety bidirectional radio controlled system

Safe radio module – reliably connects safety zones wirelessly.The UH 6900 wireless safety system offers new options and solutions in the field of functional safety. Even in areas where classic safety technology has confronted its limitations:

- If you need to securely activate an emergency disconnect for systems wirelessly in a far-away high-bay shelving unit,

- Ensure safe access to hazardous areas with continuously running machines or conveyor belts

- Or whether you need to safely stop a system to complete maintenance work on a conveyor belt or other moving equipment.

It’s no problem with UH 6900 wireless safety modules! Safe certified radio controlled technology by DOLD offers a wide variety of combinations for autonomous, mobile and stationary systems.

Wireless, safe, reliable.

The new UH 6900 is part of the SAFEMASTER W series of wireless safety systems. it offers safety-oriented, bidirectional transmission of E-stop and control functions offering greater flexibility for the protection of hazardous areas up to Cat. 4 / PL e or SIL 3. By implementing the latest radio-controlled technologies, a high degree of plant availability and safety is achieved. Two safety zones can be connected wirelessly to each other over a considerable distance. The main application areas include wide ranging systems and mobile applications such as fully automated conveyor systems and driverless autonomous transport systems.

Easy set-up procedure, configurable modules.

Quick set-up is possible thanks to pre-configured modules. The free SAFEMASTER W Manager software makes it easy to adapt the modules for different functions. Additional diagnostic functions aid set up in the field.

System overview for the DOLD UH 6900

Scope of functions.The TÜV certified UH 6900 wireless safety module is suitable for safety requirements up to Cat. 4 / PL e or SIL 3. The safety modules each have 3 two-channel safety inputs (such as emergency stop, light curtain, safety gate, etc.) and 1 safety output with 3 redundant contact paths. In addition, the modules each provide 8 inputs and outputs for user-specific control functions. Two additional status semi-conductor outputs, one indicator output for reception quality, and the USB interface provide for comprehensive diagnostic options.

Operating modes / Start options.

Safe operating modes, selectable system start – simple and functional. The following operating modes can be selected using the rotary switches: Full safety mode, cross safety mode, and safety mode with selectable optional radio control. This allows you to quickly adapt the system to your safety application. In addition, automatic, manual, or two-hand start options are available for system start.

Safety functions of the DOLD UH 6900.

Operating mode 1: Full safety mode.Safe, wireless emergency stop – safely separate system components and zones. Just two UH 6900 wireless safety modules are required to fully secure two hazardous zones. Both wireless safety modules are connected by a bidirectional safe radio connection. If a safety function is triggered (such as emergency stop, safety gate, etc.), both UH 6900 wireless safety modules shut down the entire system in both hazardous areas in a safe controlled manner.

Application example - Full safety mode:

If a safety function (emergency stop or safety gate) is activated on a system in zone 1 or zone 2, both systems are powered down in a safe and controlled manner. Only after they are shut down can persons enter the hazardous area (for instance access through releasing a safety gate lock (SAFEMASTER STS)).

Safely sequenced processes via DOLD emergency stop and access approval.

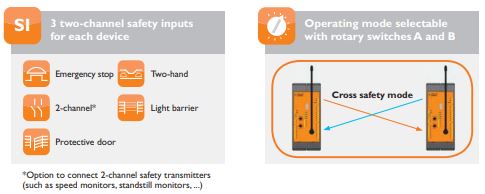

Operating mode 2: Cross safety mode.Safe, wireless protection for hazardous areas, monitoring to multiple conditions. Even complicated tasks can be handled easily with just two wireless safety modules. A safe function (access approval, start a subsequent process, etc.) is only wirelessly released if a condition, for instance in zone 1, is fulfilled. Only then is a safety function (such as access authorisation) triggered wirelessly from the other safety zone. An example: A conveyor belt in a hazardous area first has to be run in no-load operation and the belt stopped before safety gates can be released to allow access. In this operating mode, the system ensures that persons can only enter a hazardous area if the equipment or system is safe.

Application example - Cross safety mode:

A person wants to enter a secure system area (zone 2). The person activates the emergency stop in zone 1. The emergency stop signal from zone 1 is transmitted wirelessly to zone 2. The machine in zone 2 powers down in a controlled manner. As soon as it reaches a safe status, it returns a release signal for zone 2 (for instance, approve safety gate locking). Only then can the person safely enter zone 2.

Connect wirelessly, expand control and safety functions and combine functions of a mobile system and stationary system.

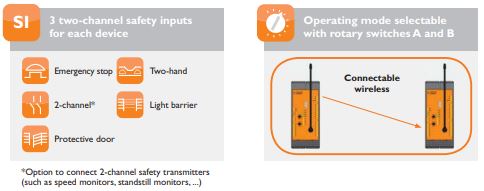

Operating mode 3: Safety mode with wireless connection option.Link safety and control functions. A UH 6900 wireless safety module monitors a production system in a hazardous area. The device first works locally without a wireless connection with its safety inputs and output. However, there is the option to connect a second UH 6900 wireless safety module (e. g. in a forklift) to the safety functions (such as emergency stop) in the production system and safely drive through the hazardous area (additional authentication can be provided by an optional infrared connection). When the wireless connection between the two modules is created, the safety functions of both devices will be active. In a hazardous situation, both the forklift and or the machine can trigger an emergency stop.. In addition, certain control functions of the system (such as the crane) can be used – entirely safely and without additional wiring work.

Application example - Safety mode with wireless connection option:

A wireless safety module secures a production system in zone 2. It first works fully autonomously without a wireless connection. A second wireless safety module is located in the forklift. To pick up produced parts on pallets, the forklift (zone 1) has to drive into the system. In order to gain access to the system (zone 2), the forklift must connect wirelessly and position itself in the specified start zone (green) and authenticate itself via infrared connection. Access to the hazardous area is approved and the forklift can drive into zone 2. The safety functions (such as emergency stop) of both modules are now active, defined control functions can be activated by the mobile vehicle. In a hazardous situation, both the forklift and the machine operator can trigger an emergency stop. Your advantage: Access to approved control functions for the loading crane and mobility and safety in the system‘s hazardous area.

DOLD SAFEMASTER W Manager - comprehensive diagnostics.

DOLD offers a free software program “SAFEMASTER W Manager” which facilitates set up, diagnostics and system logging through a simple graphic user interface. The software ensures fast diagnostics, additional live status displays and data logging, facilitating the best possible availability of machinery and systems. The integrated Spectrum Analyzer provides a quick overview of all available radio channels and potential interference.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)