DOLD Softstarters MINISTART, 1-phase controlled

DOLD soft start devices of the MINISTART family ensure that your machines start up gently and smoothly and/or minimize a wide variety of problems such as mechanical wear during the direct start of drives, the tipping or sliding of loads on transport belts, pressure surges in the lines of pump systems and much more. They reduce the wear on and increase the service life of your motors and mechanical drive components. DOLD soft start devices offer additional advantages as a simple and space-saving installation provide flexible configuration options and relieve the supplying grid through reduced starting current.

| Type | Function | For three-phase motors, 400 V up to [kW] | For single-phase motors, 230 V up to [kW] | Diverse signalling outputs | Load voltage [V] | Auxiliary voltage required | Extra functions: Temperature (T) / system monitoring (N) | Width [mm] |

|---|---|---|---|---|---|---|---|---|

|

IL 9017, SL 9017 |

Standard |

|

1.5 |

|

… 230 |

|

|

35 |

| IL 9017/300 | With softstart function |

|

1.5 |

|

… 230 |

|

|

35 |

| BA 9010 | Standard | 5.5 | 1.5 |

|

… 480 |

|

|

45 |

| BN 9011 | Standard | 11 | 3 |

|

… 480 |

|

|

100 |

| BI 9028/900 | With softstart function |

|

7.5 | + | 100…480 | + | T, N | 90 |

DOLD Softstarters MINISTART, 2-phase controlled

| Type | Function | For three-phase motors, 400 V up to [kW] | Diverse signalling outputs | Load voltage [V] | Auxiliary voltage required | Extra functions: Temperature (T) / system monitoring (N) | Width [mm] |

|---|---|---|---|---|---|---|---|

| RP 9210/300 | with soft coasting and reverse function | 0.75 | + | 200...400 | + | T | 72 |

| GI 9014 | with soft coasting | 110 | + | ... 575 | + | T, N | 98; 145; 202 |

| GF 9016 | with soft coasting | 22 | + | … 480 |

|

T, N | 45; 52.5 |

| BA 9019 | with soft coasting | 5.5 |

|

200…480 | + | T | 45 |

| BL 9025 | with soft coasting | 11 |

|

200…480 | + | T | 90 |

| BI 9025 | with soft coasting | 15 |

|

200…480 | + | T | 90 |

| UH 9018 | with soft coasting | 7.5 | + | ...400 |

|

T, N | 45 |

| BI 9028 | with d.c. braking | 15 | + | 200…480 | + | T, N | 90 |

| BL 9028 | with d.c. braking and standstill detection | 15 | + | 200…480 | + | T, N | 112.5 |

DOLD Softstarters MINISTART, 3-phase controlled

| Type | Function | For three-phase motors, 400 V up to [kW] | Diverse signalling outputs | Load voltage [V] | Auxiliary voltage required | Extra functions: Temperature (T) / system monitoring (N) | Width [mm] |

|---|---|---|---|---|---|---|---|

| GI 9015 | With softstart function | 800 |

|

200 ... 525 | + | T, N | 156 ... 750 |

| BA 9026 | With softstart function | 3 |

|

200 … 480 | + | T | 45 |

| GE 9015 | With softstart function | 55 | + | … 690 |

|

T | 235; 335 |

Following product are also available: GC 9012

Simple softstart units are not always the best solution for applications with changing loads and high break away forces when a smooth and linear start of a motor is required.

- Solution:

Here softstarters GI 9014 of the MINISTART series from DOLD with integrated starting current control could solve the problem. By this method drive systems with 3-phase motors can be started and stopped in an efficient way. In addition the devices can be integrated in a superior control by optional field bus modules. The status of device and plant becomes transparent.

Your advantages:

- To give the drive system a longer life

- Extremely space and cost saving by integrated motor protection: Overload, phase failure and exceeding starting time

- Integrated bridging contactor

- Limiting of starting current prevents against mains and equipment overload

- Productivity by shortened stating times on heavy duty stating and high permissible switching frequency

- Individual settings for multiple applications

- Easy to use.

Applications:

- Escalators

- Pumps Fans Conveyors and elevators

- Compressors ... for all other applications with high demand start and stop process.

Advantages:

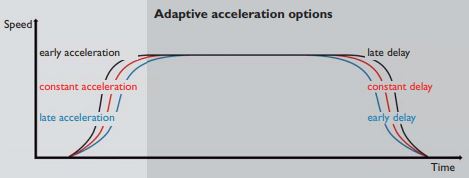

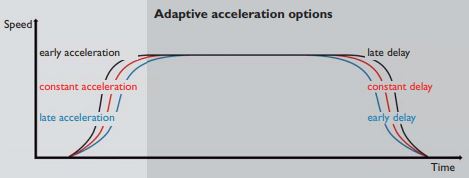

- “Adaptive acceleration control” - leading softstart technology

- Integrated Inside Delta Circuit (6-wire) across the complete product range

- Adjustable busbars for device types from 360 A - 1600 A

- Comprehensive and customer-specific motor protection functions through thermal motor model

- Emergency running function

- Creep speed operation forward and reverse

- D.C. injection brake (contactless)

- LCD display for easy setting and fault display

- Simple and time-saving commissioning as well as user-friendly operation.

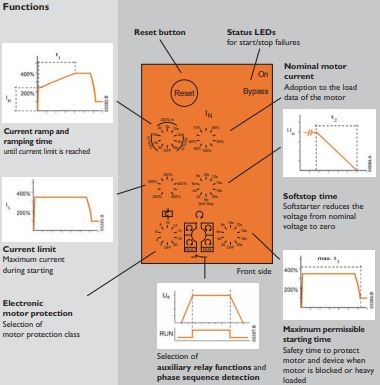

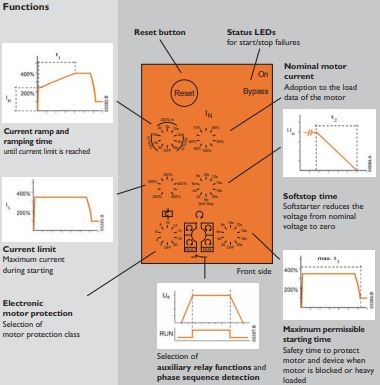

Functions:

DOLD softstarter PF 9029 overview.

The new softstarter PF 9029 from the MINISTART family by DOLD is a robust electronic control device with integrated monitoring function for soft starting for motors. With a width of 67.5 mm, the PF 9029 offers soft-starting, motor protection, voltage, and phase sequence monitoring in just one device to allow you to operate the compressor safely. The compact, 3-phase controlled softstarter PF 9029 facilitates a jolt-free, low-noise, and soft start (start-up time < 200 ms), with minimal start-up current. Current spikes and torque stops during shifting are reduced. This increases the service lives of motors and mechanical drive components. Monitoring the rotating field (clockwise) prevents motors from starting up in the wrong direction of rotation. The integrated low and overvoltage monitoring and the motor protection function in accordance with class 10 protect the motor from overload. The most important functions of the PF 9029 include jam protection in bypass mode, motor outputs up to 11 kW, recognition of absence of load, and integrated temperature monitoring for the power semiconductor. The softstarter PF 9029 provides operators an intelligent, user-friendly soft starter with comprehensive monitoring and protective functions.

Advantages and customer benefit:

- Space-saving installation in switch cabinet with just 67.5 mm construction width

- Improved reduction of start-up current

- Low level of self-heating

- Just 1 device for soft-start, motor protection, voltage and phase sequence monitoring

- Jolt-free start-up and minimized start-up current

- Increases the life span of the compressor

- No network filter required due to low interference

- Suitable for short start-up times < 200 ms

- Fast, easy installation.

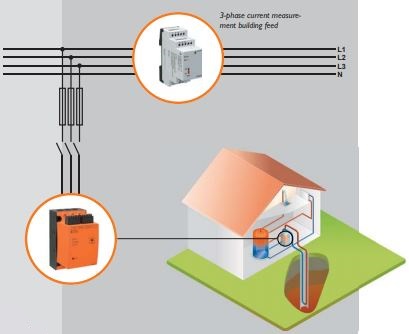

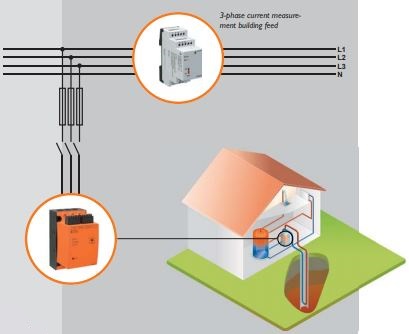

Application:

Controlling and monitoring the compressors in heat pumps in buildings with three-phase current supply. The integrated low voltage monitor protects the motor from overload, as does the motor protection function. In apartment buildings with a weak network connection (<63 A), the load status must be monitored using threephase current measurement. The heat pump can only turn on when the load condition of the network allows.

Advantages and customer benefit:

- To limit start-up current and for stable network conditions

- Jolt-free start and minimized start-up current

- Increases the life span of motors and mechanical drive components

- Protects the drive unit

- Integrated bypass conductor

- Simple operation

- Comprehensive diagnosis through LED flash code.

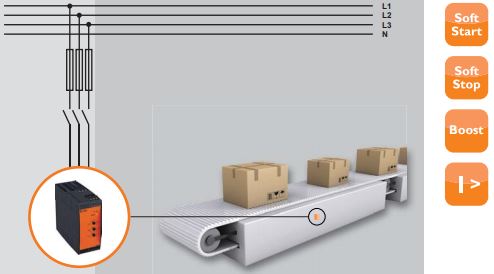

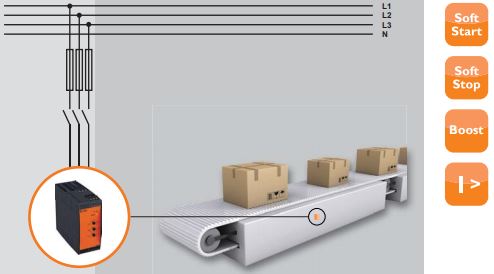

Application:

The softstarter UH 9018 is suitable for challenging applications requiring reduced torque during start-up and run-down. The device ensures that the drive can start up smoothly. This precludes the drive elements from being damaged, because no abrupt starting torque occurs when the device is switched on directly. After a successful start-up, the power semiconductor is bridged using internal relay contacts in order to minimize loss within the device. The soft start function is designed to extend the natural run-down time of the drive, also preventing an abrupt stop.

Technical Information and Features

The complete solution - DOLD softstarter with electronic motor protection.

- Demand:Simple softstart units are not always the best solution for applications with changing loads and high break away forces when a smooth and linear start of a motor is required.

- Solution:

Here softstarters GI 9014 of the MINISTART series from DOLD with integrated starting current control could solve the problem. By this method drive systems with 3-phase motors can be started and stopped in an efficient way. In addition the devices can be integrated in a superior control by optional field bus modules. The status of device and plant becomes transparent.

Your advantages:

- To give the drive system a longer life

- Extremely space and cost saving by integrated motor protection: Overload, phase failure and exceeding starting time

- Integrated bridging contactor

- Limiting of starting current prevents against mains and equipment overload

- Productivity by shortened stating times on heavy duty stating and high permissible switching frequency

- Individual settings for multiple applications

- Easy to use.

Applications:

- Escalators

- Pumps Fans Conveyors and elevators

- Compressors ... for all other applications with high demand start and stop process.

Complete motor start and motor management system.

Sophisticated drive tasks require powerful and flexible device solutions. With the softstarter GI 9015 of the MINISTART series from DOLD you are equipped with a complete motor start and motor management system. The adaptive acceleration control gives you maximum control over the acceleration and delay profiles of your motor. The intelligent softstarter learns the characteristics of the motor during startup and stopping and then performs the optimal settings. Depending on the preferred starting profile the device automatically ensures the softest possible acceleration for the load. This comprehensive functionality is complemented by great convenience, simple commissioning and intuitive operability. With the latests softstarter from DOLD at your disposal you are equipped with an intelligent, reliable and user-friendly motor start and motor management system.Advantages:

- “Adaptive acceleration control” - leading softstart technology

- Integrated Inside Delta Circuit (6-wire) across the complete product range

- Adjustable busbars for device types from 360 A - 1600 A

- Comprehensive and customer-specific motor protection functions through thermal motor model

- Emergency running function

- Creep speed operation forward and reverse

- D.C. injection brake (contactless)

- LCD display for easy setting and fault display

- Simple and time-saving commissioning as well as user-friendly operation.

Functions:

DOLD softstarter PF 9029 overview.

The new softstarter PF 9029 from the MINISTART family by DOLD is a robust electronic control device with integrated monitoring function for soft starting for motors. With a width of 67.5 mm, the PF 9029 offers soft-starting, motor protection, voltage, and phase sequence monitoring in just one device to allow you to operate the compressor safely. The compact, 3-phase controlled softstarter PF 9029 facilitates a jolt-free, low-noise, and soft start (start-up time < 200 ms), with minimal start-up current. Current spikes and torque stops during shifting are reduced. This increases the service lives of motors and mechanical drive components. Monitoring the rotating field (clockwise) prevents motors from starting up in the wrong direction of rotation. The integrated low and overvoltage monitoring and the motor protection function in accordance with class 10 protect the motor from overload. The most important functions of the PF 9029 include jam protection in bypass mode, motor outputs up to 11 kW, recognition of absence of load, and integrated temperature monitoring for the power semiconductor. The softstarter PF 9029 provides operators an intelligent, user-friendly soft starter with comprehensive monitoring and protective functions.Advantages and customer benefit:

- Space-saving installation in switch cabinet with just 67.5 mm construction width

- Improved reduction of start-up current

- Low level of self-heating

- Just 1 device for soft-start, motor protection, voltage and phase sequence monitoring

- Jolt-free start-up and minimized start-up current

- Increases the life span of the compressor

- No network filter required due to low interference

- Suitable for short start-up times < 200 ms

- Fast, easy installation.

Application:

Controlling and monitoring the compressors in heat pumps in buildings with three-phase current supply. The integrated low voltage monitor protects the motor from overload, as does the motor protection function. In apartment buildings with a weak network connection (<63 A), the load status must be monitored using threephase current measurement. The heat pump can only turn on when the load condition of the network allows.

DOLD softstarter UH 9018 model overview.

With the softstarter UH 9018 from the MINISTART series, DOLD offers a reliable softstarter available in four performance levels. The compact, two-phase controlled softstarter for an output range from 1.5 to 7.5 kW combines optimal start-up and run-down characteristics with intelligent monitoring functions. Optional functions offer additional advantages, even for challenging applications. These allow the soft starter to offer both gentle control and simplified drive monitoring in a wide variety of applications. With the UH 9018, DOLD has developed an inexpensive option that can even be a substitute for a star-delta starter. Its slim construction and the ability to snap the device onto 35 mm standard rails makes it easy to install, even in existing systems. The start-up and run-down time can be continuously controlled using potentiometers as a standard feature. The starting voltage can be individually adjusted. The boost function also allows operators to start drives with high holding torque at a standstill. The UH 9018 series is excellently equipped with regard to monitoring and security. Low voltage, phase / ignition failures or high temperatures are detected instantly and displayed using LEDs and signaling contacts. Diverse functions, flexible setting options, and a compact construction: UH 9018 makes it possible. Soft starting has never been so simple.Advantages and customer benefit:

- To limit start-up current and for stable network conditions

- Jolt-free start and minimized start-up current

- Increases the life span of motors and mechanical drive components

- Protects the drive unit

- Integrated bypass conductor

- Simple operation

- Comprehensive diagnosis through LED flash code.

Application:

The softstarter UH 9018 is suitable for challenging applications requiring reduced torque during start-up and run-down. The device ensures that the drive can start up smoothly. This precludes the drive elements from being damaged, because no abrupt starting torque occurs when the device is switched on directly. After a successful start-up, the power semiconductor is bridged using internal relay contacts in order to minimize loss within the device. The soft start function is designed to extend the natural run-down time of the drive, also preventing an abrupt stop.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)