DOLD Motor brake relays MINISTOP.

The factors of safety and efficiency are an important argument for the motor braking devices of DOLD. The wear- and maintenance-free devices can be easily installed, even in existing systems. The configurable braking current allows an optimal adjustment to machines and systems. Asynchronous motors up to 160 kW are reliably stopped with the DOLD braking devices of the MINISTOP series. This allows your machine to be brought to a standstill in only ten seconds in accordance with the EU Machinery Directive and European standards.

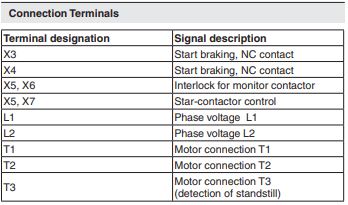

| Type | Function | Braking current adjustable up to max. [A] | Braking time adjustable up to [s] max. | Automatic zero-speed monitoring | Temperature monitoring | External brake contactor required | Diverse signalling outputs | Width [mm] |

|---|---|---|---|---|---|---|---|---|

| BI 9034 | Motor brake relay | 60 | 30 | + | + |

|

+ | 90 |

| BA 9034N | Motor brake relay | 25 | 11 | + |

|

|

|

45 |

| BI 9023 | Motor brake relay | 80 | 20 |

|

|

+ | + | 90 |

| BN 9034 | Motor brake relay | 25 | 15 | + | optionally |

|

+ | 100 |

| GB 9034 | Motor brake relay | 600 | 320 | + | optionally | from 100 A | + | 110 |

| BI 9028 | Softstart with d.c. brak | 60 | 30 |

|

+ |

|

+ | 90 |

Following product are also available: AR 9021

- Cost saving

- Compact design

- Easily appliance, no need for current measuring instrument.

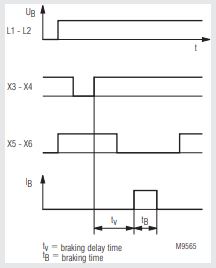

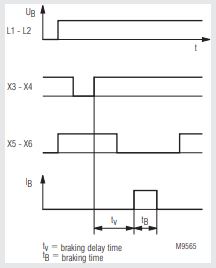

Function diagram:

Features:

- According to IEC/EN 60947-4-2

- For all single and 3-phase asynchronous motors

- DC-brake with one way rectification up to max. 32 Aeff

- Controlled by microcontroller

- Easily fitted to existing installations

- Wear free and maintenance free

- Integrated braking contactor

- DIN-rail mounting

- Adjustable braking current (controlled current)

- With automatic standstill detection

- Variante /100 with braking time control or without detection of standstill

- Width: 45 mm.

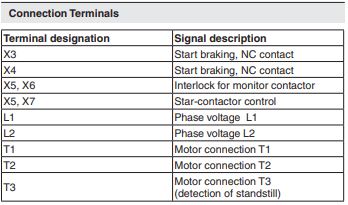

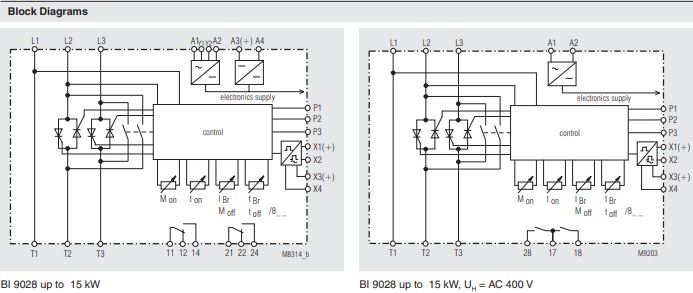

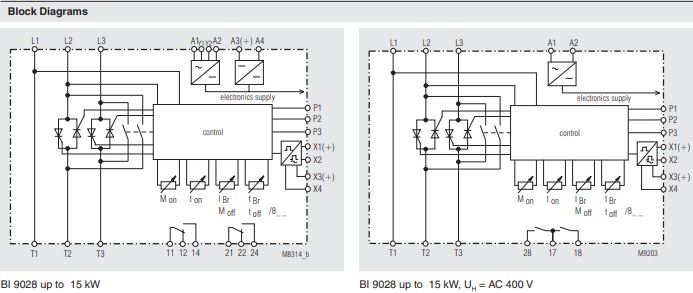

The supply voltage is connected to terminals L1-L2 and the interlock contact X5-X6 closes to enable the motor contactor. A green LED indicates operation. The motor can be started with the start button. The braking DC-voltage is generated on terminals T1 and T2 . The braking sequence is as follows: Pressing the stop button de-energises the motor contactor. The closing of X3-X4 (contact of the motor contactor) starts the braking. After a safety time the braking contactor closes for the adjusted braking time and the braking current flows through the motor.

Application:

- Saws

- Centrifuges

- Woodworking machines

- Textile machines

- Conveyors

- Easy wiring

- Space saving

Features:

- According to IEC/EN 60 947-4-2

- 2-phase motor control

- For motors up to 15 kW at 3 AC 400 V

- Separate settings for start and brake time, as well as starting and braking torque

- Galvanic isolation of control input with wide voltage range up to AC/DC 230 V

- No external motor or braking contactor necessary

- 3 auxiliary voltages up to 230 V

- monitors undervoltage and phase sequence

- 2 relay outputs for indication of status and fault

- LED-indication

- As option with voltfree contacts for start and stop

- As option with input to detect motor temperature

- BI 9028 up to 7.5 kW: 67.5 mm width, BI 9028 up to 15 kW: 90 mm width.

Technical Information and Features

DOLD motor brake relay BA 9034N overview.

- Higher safety level and more economic by short stopping cycle- Cost saving

- Compact design

- Easily appliance, no need for current measuring instrument.

Function diagram:

Features:

- According to IEC/EN 60947-4-2

- For all single and 3-phase asynchronous motors

- DC-brake with one way rectification up to max. 32 Aeff

- Controlled by microcontroller

- Easily fitted to existing installations

- Wear free and maintenance free

- Integrated braking contactor

- DIN-rail mounting

- Adjustable braking current (controlled current)

- With automatic standstill detection

- Variante /100 with braking time control or without detection of standstill

- Width: 45 mm.

DOLD motor brake relay applications and function.

Function.The supply voltage is connected to terminals L1-L2 and the interlock contact X5-X6 closes to enable the motor contactor. A green LED indicates operation. The motor can be started with the start button. The braking DC-voltage is generated on terminals T1 and T2 . The braking sequence is as follows: Pressing the stop button de-energises the motor contactor. The closing of X3-X4 (contact of the motor contactor) starts the braking. After a safety time the braking contactor closes for the adjusted braking time and the braking current flows through the motor.

Application:

- Saws

- Centrifuges

- Woodworking machines

- Textile machines

- Conveyors

DOLD MINISTART Softstarter With DC-Brake BI 9028.

- Softstart and brake in one unit- Easy wiring

- Space saving

Features:

- According to IEC/EN 60 947-4-2

- 2-phase motor control

- For motors up to 15 kW at 3 AC 400 V

- Separate settings for start and brake time, as well as starting and braking torque

- Galvanic isolation of control input with wide voltage range up to AC/DC 230 V

- No external motor or braking contactor necessary

- 3 auxiliary voltages up to 230 V

- monitors undervoltage and phase sequence

- 2 relay outputs for indication of status and fault

- LED-indication

- As option with voltfree contacts for start and stop

- As option with input to detect motor temperature

- BI 9028 up to 7.5 kW: 67.5 mm width, BI 9028 up to 15 kW: 90 mm width.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)