DOLD Semiconductor contactors/relays POWERSWITCH

Solid state contactors and relays from DOLD are the first choice everywhere that high switching frequencies and cycles in the industry are needed. They conduct switching and control tasks especially efficiently in numerous applications in industrial and building technology. Their long service life due to wear-free switching is the reason for this. DOLD also has an innovative answer to the problem caused by switching with high load currents, the severe heating of solid state contactors and relays: the use of DCB processes (Direct Copper Bonding) optimizes the heat dissipation in the power stage of the device. This ensures the operational security of your system. Solid state conductors are also used in other applications such as heating, lighting, et cetera.

| Type | Function | Load current [A] | Load voltage AC to [V] | Auxiliary voltage DC [V] | On/Off Input control [V] | Analog On/Off Input control | Temperature monitoring | Signalling output | Width [mm] | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 pole | 2 pole | 3 pole | DC | AC / DC | AC | ||||||||

| PH 9260 | Semiconductor relay | 25; 50; 100; 125 |

|

|

600 |

|

4…32 | 18…36; 85…265 |

|

|

|

|

45 |

| PH 9260.92 | Semiconductor relay / - contactor |

|

2 x 32; 2 x 48 |

|

480 |

|

18...30 |

|

|

|

|

|

45 |

| PH 9260/042 | Semiconductor relay / - contactor | 25; 50 |

|

|

480 |

|

|

|

|

4…20 mA |

|

|

45 |

| PH 9270 | Semiconductor relay with load circuit monitoring | 40 |

|

|

480 | 32 | 20...32 |

|

|

|

|

|

45 |

| PH 9270/003 | Semiconductor relay / - contactor with load current measurement | 25; 45 |

|

|

240 |

|

20...32 |

|

|

|

|

|

45 |

| PK 9260 | Semiconductor relay / - contactor for ohmic loads | to 88A |

|

|

600 |

|

18...30 |

|

100... 230 |

|

|

|

45 |

| BF 9250 | Semiconductor contactor | 10; 25; 50 | 6,5; 15; 25 | 5; 10; 15 | 480 |

|

|

24; 110...230 |

|

|

+ | + | 22.5; 45; 90 |

|

BF 9250/ _ _8 |

Semiconductor contactor | 10; 25; 50 | 6,5; 15; 25 | 5; 10; 15 | 480 |

|

4…32 |

|

|

|

|

|

22.5; 45; 90 |

| BF 9250/001 | Semiconductor contactor with temp. monitoring | 10; 25; 50 | 6,5; 15; 25 | 5; 10; 15 | 480 | 24 | 4…32 |

|

|

|

+ | + | 22.5; 45; 90 |

| BF 9250/002 | Semiconductor contactor with full-wave control | 10; 25; 50 |

|

|

480 | 24 |

|

|

|

4…20 mA / 0…10 V | + |

|

22.5; 45; 90 |

| BF 9250/042 | Semiconductor contactor with optimized pulse cycles | 10; 25; 50 |

|

|

480 | 24 |

|

|

|

4…20 mA / 0…10 V |

|

|

22.5; 45; 90 |

| BH 9251 | Semiconductor contactor with load circuit monitoring | 10; 20; 40 |

|

|

400 |

|

|

9,6… 270 |

|

|

+ | + | 45; 67.5; 112.5 |

Semiconductor relay: for screwing on the heat sink; Semiconductor contactors: with integrated heat sink, top hat rail mounting.

Your advantages at a glance:

- Immediately ready for use thanks to optimally adapted heat sinks

- Long service life for high system availability

- Noiseless and wear-free switching

- Simple mounting on the heat sink

- Easy integration into existing automation systems

- Compact design from 22.5 mm overall width

- 1-, 2- and 3-pole versions available

- Use even under extreme environmental conditions (vibration and shock resistant).

Your advantages at a glance:

- Long service life for high system availability

- Noiseless and wear-free switching

- Simple mounting by snapping onto DIN rail

- Easy integration into existing automation systems

- For 1-, 2- or 3-pole loads

- Available with UL approval

- With load circuit monitoring (BH 9251)

Monitors:

- Failure of a heating element ≥ 190 W / 380 W / 760 W

- Broken wire detection

- Short circuits between windings of a heating element.

Function:

- Voltage compensation: The unit includes voltage compensation of ± 20 %. Only fault caused by defective heating elements are detected. Current changes caused by voltage fluctuations are ignored.

- Failure of one heating element: If the current decreases from the adjusted value by 8 % of the total value the monitoring output switches off. The failure of one heating element ≥ 190 W will be detected. The control input X1-X2 has to be closed at least 100 ms to allow current sensing.

- Broken wire detection in the load circuit: A broken line in the load circuit is monitored. The output relay switches off.

- Overcurrent in the load circuit: If the current increases from the adjusted value by 10 % of the total value the monitoring output switches off. The semiconductor remains active. If the overcurrent decreases to normal current the output relay switches on again. With this function shorts between windings inside the heating elements are detected. At an overcurrent ≥ 30% of the total value the output relay switches off together with the semiconductor. This state will be stored. By switching the voltage off and on at L the semiconductor comes on again if there is no overcurrent. The monitoring output closes. This function is used to protect the device against overload.

- Temperature monitoring: The temperature detection gets active when the temperature on the semiconductor is to high. The output relay switches off together with the power semiconductor. It the temperature goes back to normal monitoring output and the semiconductor are switched on again. The time disconnection depends on the ambient temperature.

Technical Information and Features

More functionality, more possibilities in DOLD Solid-state relay / contactor.

Solid-state relays of the POWERSWITCH series are ideally suited for mounting on existing cooling surfaces and allow fast and simple mounting with just two screws. With a narrow width from 22.5 mm, the solid-state relays are absolutely space-saving. The DCB technology (Direct-Copper-Bonding-Process) ensures very good heat transfer properties. Depending on the property of the heat sink, continuous currents of up to approx. 90 A are possible. If a large number of resistive loads have to be switched, the solid-state relays can be mounted on a collective heat sink. Depending on the application, it is recommended to protect the solid-state relays against short circuits with special fuses. The solid-state relays offer a wide range of applications, e.g. in injection moulding machines in the plastics and rubber industries, in packaging machines, soldering systems and in the food industry. Solid-state contactors of the POWERSWITCH series consist of a solid-state relay plus an optimized heat sink and are therefore ready for immediate use. Depending on the version, currents of up to 50 A are permitted. Like all solid-state switching devices, the solid-state contactors also impress with their narrow and space-saving design. Thanks to the pre-dimensioned heat sink, the devices can easily be snapped onto a DIN rail or mounted on carrier plates using fastening screws.Your advantages at a glance:

- Immediately ready for use thanks to optimally adapted heat sinks

- Long service life for high system availability

- Noiseless and wear-free switching

- Simple mounting on the heat sink

- Easy integration into existing automation systems

- Compact design from 22.5 mm overall width

- 1-, 2- and 3-pole versions available

- Use even under extreme environmental conditions (vibration and shock resistant).

DOLD solid-state contactors, also with load monitoring

The solid-state contactors of the POWERSWITCH series are particularly suitable for installation in switch cabinets due to their simple snap-on mounting on the DIN rail and are available in 1-, 2- and 3-pole versions. Optionally up to 3 separate solid-state contactors in one device. The devices are characterized by a compact and space-saving design and allow fast mounting by snapping onto the DIN rail. Due to the ready-to-use design, the devices are immediately ready for use. With the device characteristics „zero point switching“ or „instantaneous switching“ you are equipped for all applications with AC loads. Whether current monitoring, load control or analogue control, the solid-state contactors offer a wide range of applications, such as switching motors, heaters, valves or lighting. Special solid-state contactors can also monitor the load circuit. The solid-state contactors operate in a load voltage range of up to 600 V and, thanks to the wide control voltage range, can be operated with a PLC or simple temperature controllers. The devices cover a current range up to 90 A with only a few versions.Your advantages at a glance:

- Long service life for high system availability

- Noiseless and wear-free switching

- Simple mounting by snapping onto DIN rail

- Easy integration into existing automation systems

- For 1-, 2- or 3-pole loads

- Available with UL approval

- With load circuit monitoring (BH 9251)

DOLD semiconductor contactor with current monitoring BH 9251 overview.

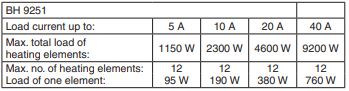

To monitor max. 12 parallel connected heating elements in packaging machines, plastic moulding machines, blister packaging machines etc. Number-/load of heating elements to be connected to BH 9251, at load voltage AC 230 V.Monitors:

- Failure of a heating element ≥ 190 W / 380 W / 760 W

- Broken wire detection

- Short circuits between windings of a heating element.

Function:

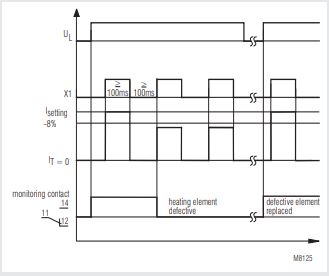

- Voltage compensation: The unit includes voltage compensation of ± 20 %. Only fault caused by defective heating elements are detected. Current changes caused by voltage fluctuations are ignored.

- Failure of one heating element: If the current decreases from the adjusted value by 8 % of the total value the monitoring output switches off. The failure of one heating element ≥ 190 W will be detected. The control input X1-X2 has to be closed at least 100 ms to allow current sensing.

- Broken wire detection in the load circuit: A broken line in the load circuit is monitored. The output relay switches off.

- Overcurrent in the load circuit: If the current increases from the adjusted value by 10 % of the total value the monitoring output switches off. The semiconductor remains active. If the overcurrent decreases to normal current the output relay switches on again. With this function shorts between windings inside the heating elements are detected. At an overcurrent ≥ 30% of the total value the output relay switches off together with the semiconductor. This state will be stored. By switching the voltage off and on at L the semiconductor comes on again if there is no overcurrent. The monitoring output closes. This function is used to protect the device against overload.

- Temperature monitoring: The temperature detection gets active when the temperature on the semiconductor is to high. The output relay switches off together with the power semiconductor. It the temperature goes back to normal monitoring output and the semiconductor are switched on again. The time disconnection depends on the ambient temperature.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)