DOLD Speed controllers and phase controllers

The speed controllers from DOLD especially serve the simple speed controlling of pumps and fans to adjust the load on the drive machine. In comparison to frequency converters, they provide with substantially few EMC problems because no shielded wires are necessary. Possible applications are the speed controlling of exhaust fans for large kitchens.

| Type | Function | Leistung [kW] | Controlled phases | Diverse signalling outputs | External start signal | Temperature monitoring | Housing style: Width [mm] | |

|---|---|---|---|---|---|---|---|---|

| 1 AC - Motoren 230 V | 3-phase AC-motors 400 V | |||||||

| IN 9017 | With analog control 4-20mA; 0...10V | 0.3 |

|

1 |

|

+ | + | Distribution board: 53 |

| SX 9240.01 | Standard | 1.5 |

|

1 | + | + | + | for outdoor installation: 100; 122 |

| SX 9240.03 | Standard |

|

5.5 | 3 | + | + | + | for outdoor installation: 100; 122; 168 |

Technical Information and Features

DOLD MINISTART phase controller IN 9017 overview.

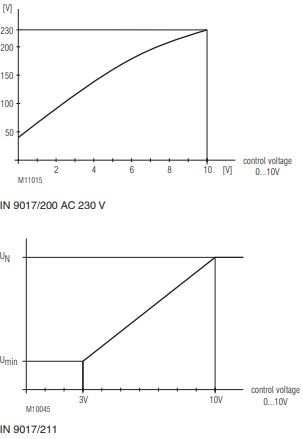

Phase controllers robust electronic units to control the voltage by phase chopping. The Phase chopping angle is adjusted on a control input. (IN 9017/100: 4 ... 20 mA, IN 9017/200: 0 ... 10 V) verstellt. The variant IN 9017/211 is realised with 0…10V input and voltfree contact input Q1, Q2. When contact input Q1, Q2 is open the output remains off at 0-3 V. With 3V control voltage the voltage adjusted on potentiometer Umin is switched on. When rising the control voltage continuously up to 10 V on the input, the output voltage increases up to AC 230 V. By closing the contact on Q1,Q2 the the output supplies the max. voltage.

DOLD speed controller, 1-phase SX 9240.01 overview.

- According to IEC/EN 60 947-1, IEC/EN 60 947-4-2- For speed control of 3-phase asynchronous motors up to 5.5 kW

- Speed adjustment by potentiometer on the front

- Additional galvanic separated control input for external speed control 0 ... 10 V

- Umin and Umax setting accessable behind screw cover

- Large motor voltage range

- Integrated temperature monitoring

- Fullfills the EMC requirement according to IEC/EN 61 000-6-4 limit class B, therefore screened wires are not necessary between motor and controller

- 2 changeover monitoring contacts

- LED indicators for alarm and status

- Connection for thermistor to monitor temperature

- 100 mm and 122 mm width.

Functions.

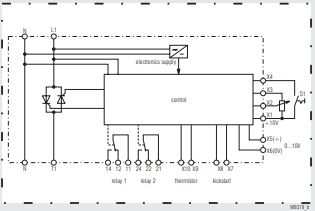

Speed controllers are electronic devices designed to enable the speed control of 3-phase induction motors. The SX 9240 is a phase chopper device based on a thyristor circuit. The control input "Kickstart", bridge X7-X8, allows to ramp up the motor voltage to nominal value after start. After that the voltage is ramped down again to the required value with corresponding speed. The speed adjustment is made by a potentiometer on the front or by an external 0 ... 10 V input. The adjustment with the higher setting will take the control of the voltage/speed.

- Temperature sensing.

The temperature of the power semiconductors are monitored. If the permitted highest temperature is exceeded, motor, relay 1 and relay 2 are switched off. The red LED flashes code 1. This Alarm can only be reset after cooling down the device and temporarily cutting the auxiliary supply of the unit.

- Motor temperature monitoring.

A thermistor can be connected to terminals X 9 - X 10. If the permitted motor temperature is exceeded the motor, relay 1 and relay 2 are switched off. The red LED flashes code 4. The unit remains in fault status until the failure is removed and the power supply is switched off and on again. If no thermistor is connected, X 9 - X 10 must be bridged.

- ON-OFF switch.

The ON-OFF switch is not edge triggered. If the switch is in position ON, the motor will start after the voltage is connected.

- Frequency test.

When the unit is connected to voltage, the frequency is measured. If the frequency is out of the permitted limits 50/60 Hz ± 10 %, relay 1 and relay 2 are switched off. The red LED flashes code 2. The unit remains in fault status until the failure is removed and the power supply is switched off and on again.

- Relay function.

Relay 1 (11-12-14): Energises when the unit is switched on and deenergises when the unit is switched off or goes into failure mode. Relay 2 (21-22-24): Energises when the unit is switched on and deenergises when the unit is switched off or goes into failure mode.

DOLD speed controller, 3-phase SX 9240.03 series.

- According to IEC/EN 60 947-1, IEC/EN 60 947-4-2- For speed control of 3-phase asynchronous motors up to 5.5 kW

- Speed adjustment by potentiometer on the front

- Additional galvanic separated control input for external speed control 0 ... 10 V, 0 ... 20 mA, 4 ... 20 mA

- Umin and Umax setting accessable behind screw cover

- Large motor voltage range • Integrated temperature monitoring

- Fullfills the EMC requirement according to IEC/EN 61 000-6-4 limit class B, therefore screened wires are not necessary between motor and controller

- 2 changeover monitoring contacts

- LED indicators for alarm and status

- Connection for thermistor to monitor temperature

- 100 mm, 122 mm and 168 mm width.

Speed control of fans and pumps.

Speed control only works if the torque of the driven load rises with a quadratic function relative to the speed. Usually this is given with fans and pumps. Suitable motors: Asynchronous motors designed for voltage control (Rotor material Silumin or similar, isolation class F).

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)