Technical Information and Features

DOLD VARIMETER EDS insulation fault detection system for non-earthed systems.

The reliability of the systems can be improved by using nonearthed power supply systems (IT systems), since the onepole direct connection of the power supply to the ground remains maintained and the system can continue with its operation. Protective elements such as the line circuit breaker or fuses will respond only when a second error occurs. Immediate removal of the fault is in this case necessary. DIN VDE 0100-410 also recommends the first insulation fault in IT systems to be removed as soon as possible. A device for insulation fault detection, also known as IFLS (Insulation Fault Location System), enables a fast localisation of insulation faults in an non-earthed power supply system. It is integrated within the insulation monitoring device and in case of a fault, it will supply a test current between the live line and the ground. The insulation fault will be localised with the aid of the residual current transformer in the consumer's outflow. The insulation fault detection system of the VARIMETER EDS family (Earth-Fault Detection System), which consists of the test current transformer RR 5886 and the insulation fault detection device RR 5887, will automatically localise the fault source. You will receive all necessary information about the faulty circuit and consumer's outflow during operation, which is of particularly great importance in widely diffused and complex systems. The maintenance and repair of your system can be planned as optimally as possible thanks to it. VARIMETER EDS is appropriate to use in most various areas.

Functioning principle of an insulation fault detection system (EDS).

The search procedure of the test current generator RR 5886 is normally activated by an insulation monitoring device when the response value is exceeded. The test current generator will then start supplying a test signal to the IT system. This limited test current will be evaluated in connection with the insulation fault detecting device RR 5887 and the residual current transformer connected to it, and the insulation fault will be in this way localised in the IT system. By connecting several insulation fault detection devices via one RS 485 bus connection, the number of measuring channels can be increased in increments of either 4 or 8 channels and the search for the insulation faults in widely diffused non-earthed power supply systems is refined in this way. Via the Modbus RTU interface, insulation fault current values can optionally be read out from the connected devices.

Field:

- Power plants and industrial systems

- Ship building industry

- Transportation technology

- Hospitals

Two different alarm levels, pre-warning and alarm, enable an early detection of faulty consumers. The insulation fault detection system of the VARIMETER EDS family can be operated more intuitively and simply thanks to automatic adjustment of the residual current transformer and clear design of adjusting and displaying units. The early detection and localisation of insulation faults enable their fast and target-oriented removal. As a user, you have many advantages from the operational safety and great availability of your IT system.

Advantages:

- Automatic and fast localisation of faulty circuits

- Increased reliability and availability of the system

- Optimal planning of maintenance and repair work

- No manual and time-consuming fault detection

- Simple operation

- Monitoring of complex systems.

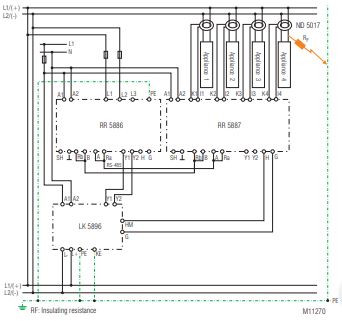

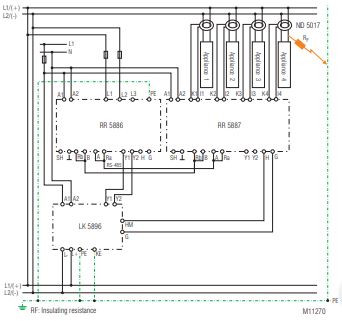

Insulation fault detection - Block diagram.

The example of the block diagram shows the basic structure of selective insulation monitoring using the test current generator RR 5886 and the insulation fault detection device RR 5887. As soon as an insulation monitoring device installed in an IT system, such as, for instance an LK 5895, reaches its response value, a test current generator will be activated by it and will automatically start the insulation fault detection process. The test signals generated are collected and evaluated by the connected residual current transformer ND 5017. Light emitting diodes which are allocated to the respective transformer, will enable simple localisation of a faulty consumer outflow. Due to the fact that the insulation monitoring device LK 5896 does not influence the insulation fault detection process, the test current generator will generate a switch-off signal at its terminals, for the measurement circuit of the insulation monitoring device.

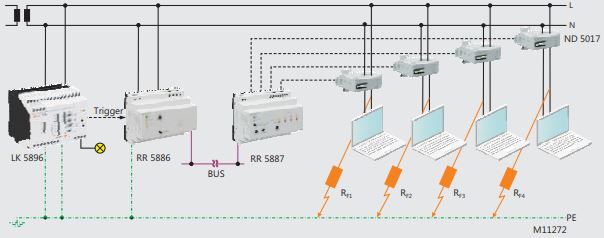

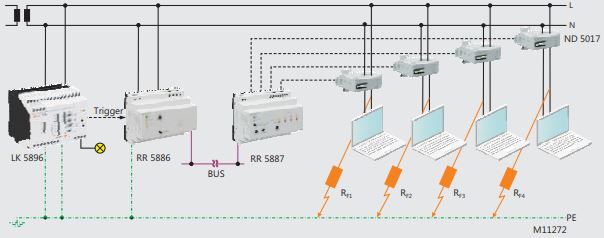

Example of application of the DOLD insulation fault detection system RR 5886 / RR 5887.

Devices for insulation fault detection can be easily used and are recommended in complex and widely diffused power supply systems. The insulation fault detection system is also advantageous for data centres, which are operated within a non-earthed system (IT system) for the reasons of availability and resistance to interference. The components the insulation of which has been damaged even earlier can be quickly localised and replaced even before their failure or burn-out which can sometimes be associated with data losses. Faulty circuits and consumer outflows are directly visualised on the insulation fault detection device RR 5887.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)