Fuji Electric, Specific Pressure Transmitters series

“Custom built” and made in France technology

Whatever your process Fuji Electric team of specialists is at your disposal to find the concept and solutions which are best adapted to your applications. Fuji Electric France has a Research & Development department which works closely with customers to find the best solution for their applications.Flanges, remote seal(s) and specific connections are studied and designed by a team of specialist engineers and technicians (according to customers’ specifications) and using powerful IT resources.

Absolute pressure measurement, DN50/PN40 seals

Absolute pressure measurement, DN50/PN40 seals

Relative pressure measurement with screw-in remote seal 1/2" NPT (in option with rising ring)

Relative pressure measurement with screw-in remote seal 1/2" NPT (in option with rising ring)

Level measurement

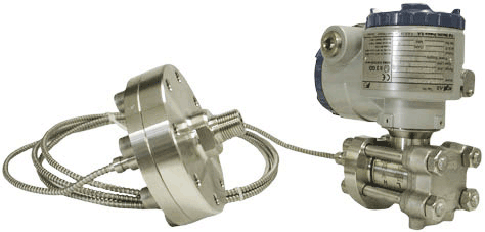

Level measurement on closed tank, DN80/PN40 capillary seals on BP side and unbending on HP side

Level measurement on closed tank, DN80/PN40 capillary seals on BP side and unbending on HP side

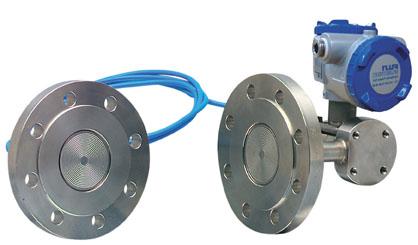

Level measurement on tank with DN80/PN40 seal and extension

Level measurement on tank with DN80/PN40 seal and extension

Flow measurement

Weak flow gas or liquid measurement, integrated orifice mounting

Weak flow gas or liquid measurement, integrated orifice mounting

Flow gas or liquid measurement with direct mounting Pitot tube and 3 valves manifold

Flow gas or liquid measurement with direct mounting Pitot tube and 3 valves manifold

Large stock of stainless steels and different noble materials (Hastelloy C, Tantalum, Duplex, etc).

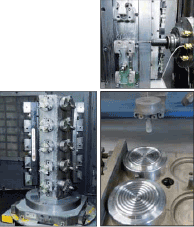

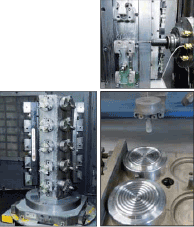

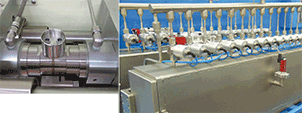

2-Part machining and production

A workshop comprising a range of machining centres and digital command towers (CN) provides high flexibility to the production unit set up in the new Cournon d’Auvergne factory.

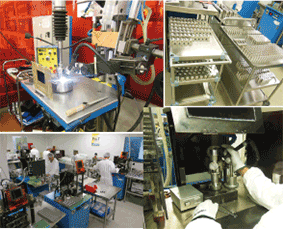

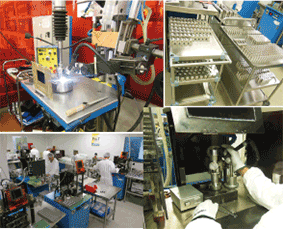

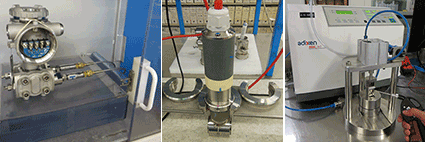

3-TIG welding stations in clean room

Manually or automatically-operated, Tungsten Inert Gas welding (TIG) technology guarantees robust and reliable assemblies. These specialised welding facilities enable us to assemble the diaphragm seals, the capillaries and directly mount the seals on the transmitters. All welds are checked by a Helium mass spectrometer to guarantee the integrity of the weld. This installation, which is combined with the other study, machining, assembly and calibration resources, enables Fuji Electric France to control the whole pressure transmitter manufacturing chain and so provide a precise and reliable product which meets the customer’s requirements to the letter.

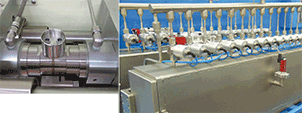

4-Cells filling

Filling pressure transmitter measurement cells is a vital manufacturing stage. Different oils may be incorporated according to the process and the customer’s industrial environment.

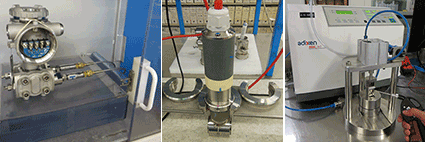

5-Calibration benches

All Fuji Electric France pressure transmitters are calibrated on computer based automatic benches. The recent design of these calibration systems guarantees high precision and perfect detection of the slightest fault.

Whatever your process Fuji Electric team of specialists is at your disposal to find the concept and solutions which are best adapted to your applications. Fuji Electric France has a Research & Development department which works closely with customers to find the best solution for their applications.Flanges, remote seal(s) and specific connections are studied and designed by a team of specialist engineers and technicians (according to customers’ specifications) and using powerful IT resources.

Transmitters for pressure measurement

Absolute pressure measurement, DN50/PN40 seals

Absolute pressure measurement, DN50/PN40 sealsLevel measurement

Flow measurement

Weak flow gas or liquid measurement, integrated orifice mounting

Weak flow gas or liquid measurement, integrated orifice mounting Flow gas or liquid measurement with direct mounting Pitot tube and 3 valves manifold

Flow gas or liquid measurement with direct mounting Pitot tube and 3 valves manifold2 sites dedicated to transmitters production

1-Raw materialsLarge stock of stainless steels and different noble materials (Hastelloy C, Tantalum, Duplex, etc).

2-Part machining and production

A workshop comprising a range of machining centres and digital command towers (CN) provides high flexibility to the production unit set up in the new Cournon d’Auvergne factory.

3-TIG welding stations in clean room

Manually or automatically-operated, Tungsten Inert Gas welding (TIG) technology guarantees robust and reliable assemblies. These specialised welding facilities enable us to assemble the diaphragm seals, the capillaries and directly mount the seals on the transmitters. All welds are checked by a Helium mass spectrometer to guarantee the integrity of the weld. This installation, which is combined with the other study, machining, assembly and calibration resources, enables Fuji Electric France to control the whole pressure transmitter manufacturing chain and so provide a precise and reliable product which meets the customer’s requirements to the letter.

4-Cells filling

Filling pressure transmitter measurement cells is a vital manufacturing stage. Different oils may be incorporated according to the process and the customer’s industrial environment.

5-Calibration benches

All Fuji Electric France pressure transmitters are calibrated on computer based automatic benches. The recent design of these calibration systems guarantees high precision and perfect detection of the slightest fault.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)