Fuji Electric FRENIC-Mega (FRN G1) frequency inverter series for general purpose

- Able to drive induction and permanent magnet synchronous motors

- Motor control methods: PG vector control, sensorless vector control, dynamic torque vector control, and V/f control

- Improved durability in overload operation:

- HD (high duty) spec: 200% for 3 sec / 150% for 1 min

- LD (low duty) spec: 120% for 1 min - Built-in EMC filter as standard

- STO compliant to EN 61800-5-2 SIL 2 and EN ISO 13849-1 PL d Cat. 3

- Ability to handle up to 3 simultaneous option cards (3 ports)

- Keypad with a USB connector

- Built-in braking transistor up to 22 kW (standard) and 160 kW (option)

- Full network support

- 4 complete motor maps

| Model | Voltage, V |

Capacity, kW |

Current, A |

V/f mode |

Enclosure IPXX |

Output frequency, Hz |

Overload capacity, % per 1 min |

Dimensions (W x H x D), mm |

Weight, kg |

Price |

|---|---|---|---|---|---|---|---|---|---|---|

| FRN0.4G1E-4E | 380-480 (3ph) | 0.4 | 1.5 | + | IP 20 | 25-500 | 150 | 110x260x132 | 1,8 | € 276,00 |

| FRN0.75G1E-4E | 380-480 (3ph) | 0.75 | 2.5 | + | IP 20 | 25-500 | 150 | 110x260x145 | 2,1 | € 324,00 |

| FRN1.5G1E-4E | 380-480 (3ph) | 1.5 | 4 | + | IP 20 | 25-500 | 150 | 150x260x145 | 2,7 | € 374,00 |

| FRN2.2G1E-4E | 380-480 (3ph) | 2.2 | 5.5 | + | IP 20 | 25-500 | 150 | 150x260x145 | 2,9 | € 453,00 |

| FRN4.0G1E-4E | 380-480 (3ph) | 4 | 9 | + | IP 20 | 25-500 | 150 | 150x260x145 | 3,2 | € 541,00 |

| FRN5.5G1E-4E | 380-480 (3ph) | 5.5 / 7.5 | 13.5 / 16.5 | + | IP 20 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 220x260x195 | 6,8 | € 713,00 |

| FRN7.5G1E-4E | 380-480 (3ph) | 7.5 / 11 | 18.5 / 23 | + | IP 20 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 220x260x195 | 6,9 | € 877,00 |

| FRN11G1E-4E | 380-480 (3ph) | 11 / 15 | 24.5 / 30.5 | + | IP 20 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 220x260x195 | 6,2 | € 1 027,00 |

| FRN15G1E-4E | 380-480 (3ph) | 15 / 18.5 | 32 / 37 | + | IP 20 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 250x400x195 | 10,5 | € 1 389,00 |

| FRN18.5G1E-4E | 380-480 (3ph) | 18.5 / 22 | 39 / 45 | + | IP 20 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 250x400x195 | 10,5 | € 1 521,00 |

| FRN22G1E-4E | 380-480 (3ph) | 22 / 30 | 45 / 60 | + | IP 20 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 250x400x195 | 11,2 | € 1 883,00 |

| FRN30G1E-4E | 380-480 (3ph) | 30 / 37 | 60 / 75 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 320x550x255 | 26 | € 2 501,00 |

| FRN37G1E-4E | 380-480 (3ph) | 37 / 45 | 75 / 91 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 320x550x255 | 27 | € 3 167,00 |

| FRN45G1E-4E | 380-480 (3ph) | 45 / 55 | 91 / 112 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 355x615x270 | 32 | € 3 850,00 |

| FRN55G1E-4E | 380-480 (3ph) | 55 / 75 | 112 / 150 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 355x675x270 | 33 | € 4 153,00 |

| FRN75G1E-4E | 380-480 (3ph) | 75 / 90 | 150 / 176 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 355x740x270 | 42 | € 5 107,00 |

| FRN90G1E-4E | 380-480 (3ph) | 90 / 110 | 176 / 210 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 535,8x740x321,3 | 62 | € 6 353,00 |

| FRN110G1E-4E | 380-480 (3ph) | 110 / 132 | 210 / 253 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 535,8x740x321,3 | 64 | € 6 806,00 |

| FRN132G1E-4E | 380-480 (3ph) | 132 / 160 | 253 / 304 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 536,4x1000x366,3 | 103 | € 8 159,00 |

| FRN160G1E-4E | 380-480 (3ph) | 160 / 200 | 304 / 377 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 536,4x1000x366,3 | 103 | € 9 916,00 |

| FRN200G1E-4E | 380-480 (3ph) | 200 / 220 | 377 / 415 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 686,4x1000x366,3 | 144 | € 11 166,00 |

| FRN220G1E-4E | 380-480 (3ph) | 220 / 280 | 415 / 520 | + | IP20 | 25--500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 686,4x1000x366,3 | 144 | € 12 718,00 |

| FRN280G1E-4E | 380-480 (3ph) | 280 / 315 | 520 / 650 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 686,4x1400x445,5 | 245 | € 18 870,00 |

| FRN315G1E-4E | 380-480 (3ph) | 315 / 355 | 585 / 740 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 686,4x1400x445,5 | 245 | € 21 223,00 |

| FRN355G1E-4E | 380-480 (3ph) | 355 / 400 | 650 / 840 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 886,4x1400x446,3 | 330 | € 23 633,00 |

| FRN400G1E-4E | 380-480 (3ph) | 400 / 500 | 740 / 960 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 886,4x1400x446,3 | 330 | € 25 893,00 |

| FRN500G1E-4E | 380-480 (3ph) | 500 / 630 | 960 / 1170 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 1006x1550x505,9 | 530 | € 32 591,00 |

| FRN630G1E-4E | 380-480 (3ph) | 630 / 710 | 1170 / 1370 | + | IP 00 | 25-500 | 150%/1 min; 200%/3.0 sec (HD mode); 120%/1 min (LD mode) | 1006x1550x505,9 | 530 | € 35 778,00 |

Fuji Electric frequency inverter FRENIC-Mega is the best in class vector control for general-purpose inverters

PG vector control

Effective in providing highly accurate control for applications such as printing presses.

- Speed control range: 1:1500

- Speed response: 100Hz

- Speed control accuracy: ±0.01%

- Current response: 500Hz

- Torque accuracy: ±10%

* The option card is required separately.

* The above specifications may vary depending on the environment or conditions for use

Further Improved Fuji's original dynamic torque vector control

In addition to the dynamic torque vector control, the inverter has a constant tuning mode of operation that will compensate for voltage errors in the main circuit devices. The inverter also utilizes a new magnetic flux observer for more precise operation. This allows for a high starting torque of 200%, even at low speed (0.3 Hz).

Improved durability in overload operation

The inverter performs quick acceleration and deceleration tasks, at maximum power, by extending the overload time as compared with previous models. This improves the operation efficiency of the applications such as cutting machines and conveyors. Overload capability: 200% for 3s and 150% for 1 min.

The standard model is available in two specifications concerning the operation load.

Expanded power ratings for built-in braking transistor

For models with power ratings up through 40Hp(LD) the dynamic braking transistor is built-in and is provided as standard. This functionality is utilized for applications where the load requires additional deceleration control such as vertical conveyance machines.

* Power ratings on models up through 15Hp(LD) also include a dynamic braking resistor.

** For 460V power ratings on models of 50Hp(LD) through 250Hp(LD) the built-in dynamic braking transistor is available upon request.

Maximizing motor performance

Speed sensor-less vector control. Useful for applications that require a high starting torque, such as the gondola type multi-level car parking tower.

- Speed control range: 1:200

- Speed response: 20Hz

- Speed control accuracy: ±0.5%

- Current response: 500Hz

- Torque accuracy: ±10%

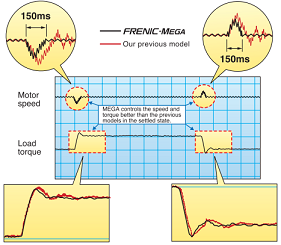

Fuji Electric vfd FRENIC-Mega series has a improved reaction to fluctuation of an impact load

When a substantial load fluctuation occurs, the inverter provides a torque response that is best in class. It controls the flux to minimize the fluctuation in motor speed while suppressing the vibration. This function is best suited for the equipment that requires stable speed operation such as a cutting machine.

Quicker response to the operation commands

The terminal response to the operation commands has an established reputation. FRENIC-MEGA has further shortened this response time, achieving an industry-best response time. This function is effective in shortening the tact time per cycle and effective for use in the process including frequent repetitions.

Accommodating various applications

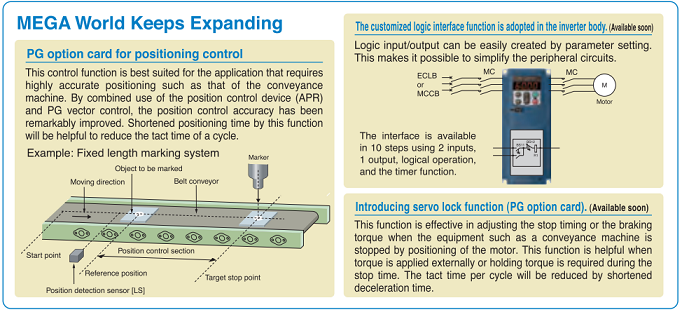

- The pulse train input function is provided as standard.It is possible to issue a speed command with the pulse train input (single-phase pulse and a sign of command value) from a pulse generator, etc. (Maximum pulse input: 100kHz)

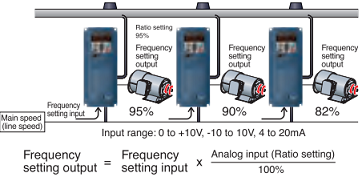

- Speed Ratio operation

The Ratio operation function is used to adjust the speed differences between two different sections of a machine/process. Using one main speed reference, two or more inverters can have their speeds modified by an analog ratio signal. On conveyor systems, one conveyor can be made to run slightly faster to match speed with another based on gear box ratio differences.

- Optimum function for preventing an object from falling

The reliability of the brake signal was increased for uses such as vertical conveyance. Conventionally, the current value and the frequency have been monitored when the brake signal is output. By adding a torque value to these two values, the brake timing can be adjusted more easily.

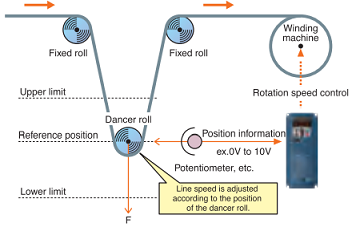

- Dancer control function optimized for winding control

The PID value, which is calculated by comparing the target value and the feedback value, is added to or subtracted from the reference line speed. Since the PID calculator proportional gain can be adjusted to have a MEGA FAST response. The inverter can be applied to automatic control systems where quick response may be required.

- "Total" protection of the braking circuit

The inverter protects the braking resistor by monitoring the braking transistor operation. The inverter outputs an exclusive signal on detection of the braking transistor abnormality. A circuit for shutting off the input power supply must be provided outside of the inverter. When this signal is output, the power is shut off; thus protecting the braking circuit.

- Extended functions for various applications

(1) Safety function meets EN954-1 Cat.3. (2) Analog inputs: voltage input through 2 terminals with polarity, current input through 1 terminal (3) Slow flowrate level stop function (Pressurized operation is possible before slow flowrate operation stop.) (4) Non-linear V/f pattern at 3 points (5) Dummy failure output function (6) Selection of up to the 4 motors (7) S-curve accel./decel. range setting (8) Detecting loss of PID feedback.

Fuji Electric drive FRENIC-Mega has a multi-function Keypad

Features:- LCD with intelligent back-light feature for better viewing

- Large 7-segment LED with 5 digit display for excellent visibility from a distance

- Quick setup parameter list that can be customer modified

- Fully functional Remote/Local key for switching between operation commands and speed references

- 3 different parameter sets can be saved and copied

- Various display languages English, Spanish, French, German, Italian and Japanese

Keypad with USB port

- The built-in USB port allows use of a personal computer loader software for easy information control- A variety of data from the inverter can be saved in keypad memory, allowing you to check the information at any time

- Data can be transferred from the USB port of the keypad directly to the computer (personal computer loader) at the manufacturing site.

- Periodical collection of life information can be carried out efficiently.

- The real-time tracing function permits the operator to check the equipment for abnormality

Built-in network functionality

- RS-485 communication is provided as standardIn addition to the RJ-45 connection port which is shared with the inverter keypad, RS-485 terminals are provided as standard on the control terminal board allowing multi-drop network connections to be made easily.

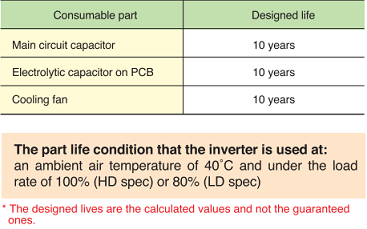

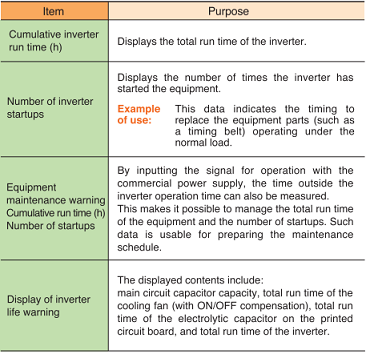

Fuji Electric drive FRENIC-Mega series has a prolonged service life and improved maintenance alarm function

The design life for the replaceable components of the inverter is 10 years.

The inverter is loaded with many different functions for facilitating maintenance of the equipment.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)