Fuji Electric, Ultrasonic flow meters for liquids

The Fuji Electric engineers have developed innovative solutions for ultrasonic flow measurement : PORTAFLOW-C (portable), M-FLOW, TIME DELTA-C (fixed mounted) and the new FST (flange mounted). These instruments are based on transit-time measuring method and are particularly suitable for liquid flow measurement (temperature -40 to +200°C). Sensors are attached to the outside of the pipeline without cutting or drilling, except for the FST flowmeter.

- Improved Sensitivity and Zero-Point Stability

- Accepts Various Types of Fluid

- Convenient Configuration and Data Management from PC

- Low Maintenance

- Flexible Output Terminal

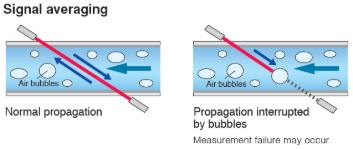

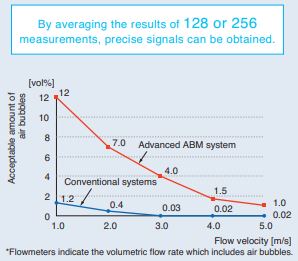

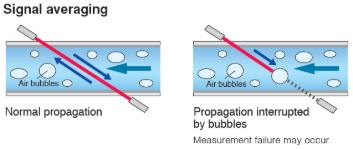

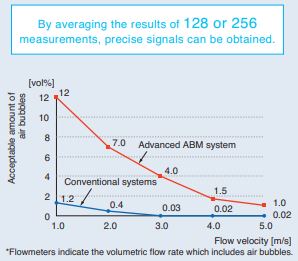

Fuji Electric’s advanced anti-bubble measurement technology reduces the interference effect.

- Thermal or electric power plants : flow rate measurement of the boiler water supply, condenser circulating pump and turbine oil.

- Heating/cooling systems : flow rate measurement of hot water and chilled water in heating and cooling.

- Stations thermals : water extracted quantity measurement.

- Food manufacturing plant : flow rate measurement of raw material and washing water

- Other industries : flow measurement of all homogeneous liquids capable of ultrasonic wave propagation (service water, sewage, industrial water, seawater, pure water, water for irrigation, oil etc.)

- Improved Sensitivity and Zero-Point Stability

- Accepts Various Types of Fluid

- Convenient Configuration and Data Management from PC

- Low Maintenance

- Flexible Output Terminal

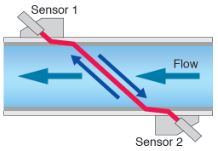

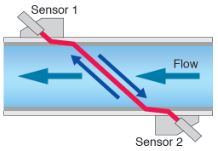

Fuji Electric measurement principle - Transit time difference method.

A pair of sensors are installed on the outside wall of the pipe, facing each other slantingly. Ultrasonic waves are propagated diagonally between the upstream and downstream sensors. In one case, the wave is "carried" by the fluid, in the other it is "braked". It therefore takes a different time to switch from one sensor to another. This difference is proportional to the measurement principle of ultrasonic flowmeters for liquid speed and therefore to the flow rate of the fluid.

Fuji Electric Ultrasonic Flowmeters anti-bubble measurement (ABM) system.

The 32 bits microprocessor based electronics allows a high accuracy (±1%), a response time of 1 second or less, a very good immunity to air bubbles (ABM system) and to change of fluid pressure and temperature (continuous calculation of sonic speed).

Fuji Electric’s advanced anti-bubble measurement technology reduces the interference effect.

Hardly Affected by Fluid Pressure and Temperature.

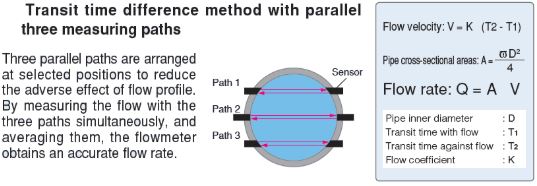

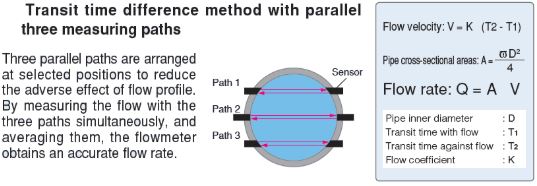

The sensors placed on upstream and downstream emit ultrasonic pulse in turn, and detect the transit time difference of the pulse to calculate the flow rate. Highly accurate measurement can be obtained regardless of the type of fluid.Fuji Electric flange mounted FST flowmeter - High accurate measurement.

Three pairs of sensors offer an accuracy of ± 0.2%. . The FST model is suitable for all energy-saving applications where its high precision and the absence of pressure loss help to reduce consumption and costs. The FST measurement principle is the transit time difference method with parallel three measuring paths.

Applications.

- Water supply and sewage systems : leakage investigation of water pipe and investigation of the flow direction in the water distribution pipe.- Thermal or electric power plants : flow rate measurement of the boiler water supply, condenser circulating pump and turbine oil.

- Heating/cooling systems : flow rate measurement of hot water and chilled water in heating and cooling.

- Stations thermals : water extracted quantity measurement.

- Food manufacturing plant : flow rate measurement of raw material and washing water

- Other industries : flow measurement of all homogeneous liquids capable of ultrasonic wave propagation (service water, sewage, industrial water, seawater, pure water, water for irrigation, oil etc.)

Line-up of Fuji Ultrasonic flow meters for liquids

| Models |

|

|

|

|

|

| FST | FLR M-FLOW PW |

FSV TIME DELTA-C |

FSV-L TIME DELTA-C ETENDU |

FSC PORTAFLOW-C |

|

| Mounting method | Flanges | Clamp-on outside the pipe | |||

| APPLICATIONS | |||||

| Clean liquid with no air bubbles | ++ | ++ | ++ | ++ | ++ |

| Sewage, drainage | + | + | + | + | + |

| Viscous liquids | + | + | + | + | + |

| Oil | + | + | + | + | + |

| Corrosive liquids | + | ++ | ++ | ++ | ++ |

| Non-conductive liquids | ++ | ++ | ++ | ++ | ++ |

| Low-velocity fluids | na | + | + | + | + |

| Pulsating fluids | na | (1) | (1) | (1) | (1) |

| High-temperature fluid | + | + | + | + | + |

| High-pressure fluids | + | ++ | ++ | ++ | ++ |

| MAIN SPECIFICATIONS | |||||

| Protection | IP66 | IP65 | IP66 (IP67 option) | IP67 | IP64 |

| Flange mounted | DN50, DN80, DN100 mm | na | na | na | na |

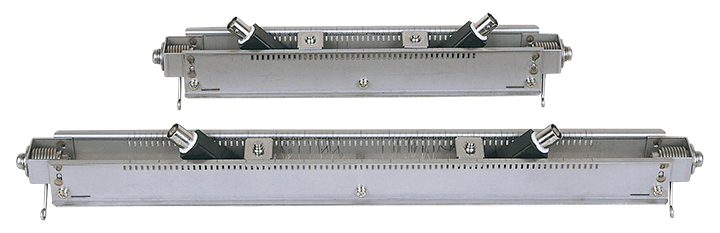

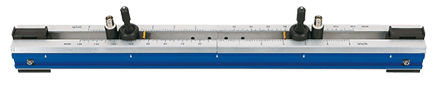

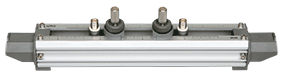

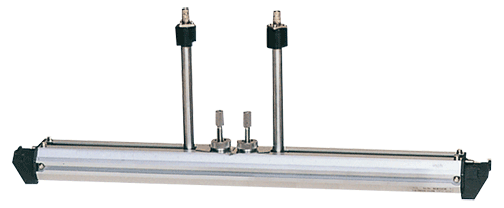

| Clamp-on detectors | na | FSSA detector 25 to 225 mm (outside diameter) / -40 to +100°c

|

|||

| na | FSSC detector 50 to 1200 mm (outside diameter) / -20 to +120°c  |

||||

| na | FSSD detector 13 to 300 mm (outside diameter) / -40 to +100°c

|

||||

| na | FSSE detector 200 to 6000 mm (outside diameter) / -40 to +80°c

|

||||

| na | FSSH detector 50 to 400 mm (outside diameter) / -40 to +200°c

|

||||

| Pressure max | PN40 | No limit | |||

| Fluid temperature | -40°C to +150°C | Depending on the detector used | |||

| Flow velocity | 0 to ±0.3…10 m/s | 0 to ±0.3…10 m/s | 0 to ±0.3…32 m/s | ||

| Accuracy | ±0.2 % | ±1.5 % | ±1.0% Depending on diameter and velocity |

||

| Power supply voltage | 100-240 V AC 50/60 Hz | 100-240 V AC 50/60 Hz ou 20-30 Vcc | 100-240 V Ac 50/60 Hz | 12 hours battery 12 V Ac ou 100-240 V AC |

|

na : Not applicable

(1) : Suitable under conditions

+ : Suitable

++ : Best suitable

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)