Fuji Electric, Thermal energy and flow calculator

ERW 700 uses input data such as flow (differential pressure), pressure, temperature and density to calculate the volume, standard volume and mass of liquids, gases and steam.

- Suitable for gas, liquids (thermo-oil, glycol, etc), steam and water

- Can be combined with all conventional volume sensors (differential pressure, vortex, turbine, dynamic pressure, cross probe, ultrasonic, MID, coriolis)

- High-precision process calculation of density, enthalpy and compressibility based on equations or extensive database.

- 2 independent 24 Bit AD converters for resistance (temperature) and current input, calculation speed 10 re-evaluations per second

- Compensation input for density signal

- Logger functions for 2 fixed dates, up to 30 monthly values, up to 800 periodic memory, 100 error memory, 100 parameter memory and min/max memory entries (31 days,12 months)

- Parameterization and operation via PC software and/or manually via a keyboard

- Separate LC display (e.g. for switch cabinet door installation)

- Extensive modular extensions for inputs and outputs

- Various special functions, such as condensate measurement, bi-directional measurement, tariff or fault counters, etc.

- Large backlit graphical display, flexible configuration.

- System monitoring in energy plants

- For heat/cold production in the middle and upper performance range

- For greater measuring accuracy and reliability requirements.

- Density determination via algorithms and tables

- Heat capacity via algorithms and tables Water/ Steam Calculation standard IAP WS IF-97 (water steam table)

Gases.

- Ideal gas law

- Flow correction considering temperature, pressure and compressibility

- Redlich-Kwong

- GERG 88.

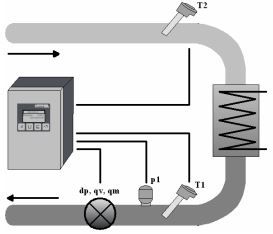

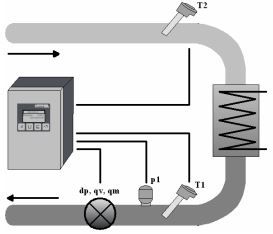

Calculation of the heat quantity and flow quantity transmitted to a heating or cooling system by a flow of liquid or which is absorbed by a flow of liquid. The heat quantity is calculated on the basis of the flow rate and the temperature difference between the supply and return. Bi-directional measurements, such as charging/discharging of heat accumulators, and multiple-tariff measurements are also possible. Furthermore, there is an input for direct density measurement of changing mixing ratios, e.g. for a water/glycol mix.

Heat quantity calculation using the flow and temperature difference input data. Volume sensor optionally assembled in supply or return line.

Steam Energy - mass (volume), flow rate, power.

Calculation of the heat quantity/flow quantity as a function of the steam flow, steam pressure and steam temperature process data. Overheated steam calculation occurs in a pressure and temperature-compensated manner. Saturated steam calculation takes place in either a pressure- or temperature-guided manner. Numerous special functions, such as bi-directional measurements or multiple-tariff measurements are possible.Calculation of the flow quantity/heat quantity in a sealed steam system using the flow, pressure and temperature input data.

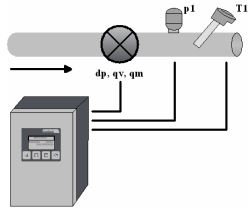

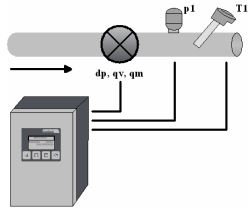

Gas / Air Energy - standard volume (mass), flow rate, power.

Calculation of the gas volume flow and the gas mass as a function of the gas flow, gas pressure and gas temperature process data. The heat quantity can also be determined. Furthermore, there is an input for direct density measurement, e.g. of changing mixing ratios.

Calculation of the flow rate (power) as a function of the flow, pressure, temperature or density process data.

Measuring device design.

The energy and flow computer ERW 700 is a state-of-the-art calculation unit. ERW 700 has a graphical display which allows users to view all the relevant measuring and calculation values. Using the menu guidance, it is possible to alter the configuration and parameters via the respective keys. Optional input and output cards are available to enhance device functioning.

The energy and flow computer consists of the following components:

- Calculation unit with integrated inputs and outputs (basic module)

- LC display unit with 4 keys

- Input cards (optional)

- Output cards (optional).

Maintenance requirements.

- Special maintenance is not required.

- Calibrated devices must be recalibrated after 5 years.

IT security.

- The computer is password protected.

- Suitable for gas, liquids (thermo-oil, glycol, etc), steam and water

- Can be combined with all conventional volume sensors (differential pressure, vortex, turbine, dynamic pressure, cross probe, ultrasonic, MID, coriolis)

- High-precision process calculation of density, enthalpy and compressibility based on equations or extensive database.

- 2 independent 24 Bit AD converters for resistance (temperature) and current input, calculation speed 10 re-evaluations per second

- Compensation input for density signal

- Logger functions for 2 fixed dates, up to 30 monthly values, up to 800 periodic memory, 100 error memory, 100 parameter memory and min/max memory entries (31 days,12 months)

- Parameterization and operation via PC software and/or manually via a keyboard

- Separate LC display (e.g. for switch cabinet door installation)

- Extensive modular extensions for inputs and outputs

- Various special functions, such as condensate measurement, bi-directional measurement, tariff or fault counters, etc.

- Large backlit graphical display, flexible configuration.

Fuji Electric thermal energy and flow calculator applications.

- Billing meter for district and local heat- System monitoring in energy plants

- For heat/cold production in the middle and upper performance range

- For greater measuring accuracy and reliability requirements.

Fuji Electric calculation methods.

Liquids.- Density determination via algorithms and tables

- Heat capacity via algorithms and tables Water/ Steam Calculation standard IAP WS IF-97 (water steam table)

Gases.

- Ideal gas law

- Flow correction considering temperature, pressure and compressibility

- Redlich-Kwong

- GERG 88.

Fuji Electric thermal energy and flow calculator principle of Operation and System Design.

Liquids - Energy, volume (mass), flow rate, power.Calculation of the heat quantity and flow quantity transmitted to a heating or cooling system by a flow of liquid or which is absorbed by a flow of liquid. The heat quantity is calculated on the basis of the flow rate and the temperature difference between the supply and return. Bi-directional measurements, such as charging/discharging of heat accumulators, and multiple-tariff measurements are also possible. Furthermore, there is an input for direct density measurement of changing mixing ratios, e.g. for a water/glycol mix.

Heat quantity calculation using the flow and temperature difference input data. Volume sensor optionally assembled in supply or return line.

Steam Energy - mass (volume), flow rate, power.

Calculation of the heat quantity/flow quantity as a function of the steam flow, steam pressure and steam temperature process data. Overheated steam calculation occurs in a pressure and temperature-compensated manner. Saturated steam calculation takes place in either a pressure- or temperature-guided manner. Numerous special functions, such as bi-directional measurements or multiple-tariff measurements are possible.Calculation of the flow quantity/heat quantity in a sealed steam system using the flow, pressure and temperature input data.

Gas / Air Energy - standard volume (mass), flow rate, power.

Calculation of the gas volume flow and the gas mass as a function of the gas flow, gas pressure and gas temperature process data. The heat quantity can also be determined. Furthermore, there is an input for direct density measurement, e.g. of changing mixing ratios.

Calculation of the flow rate (power) as a function of the flow, pressure, temperature or density process data.

Measuring device design.

The energy and flow computer ERW 700 is a state-of-the-art calculation unit. ERW 700 has a graphical display which allows users to view all the relevant measuring and calculation values. Using the menu guidance, it is possible to alter the configuration and parameters via the respective keys. Optional input and output cards are available to enhance device functioning.

The energy and flow computer consists of the following components:

- Calculation unit with integrated inputs and outputs (basic module)

- LC display unit with 4 keys

- Input cards (optional)

- Output cards (optional).

Maintenance requirements.

- Special maintenance is not required.

- Calibrated devices must be recalibrated after 5 years.

IT security.

- The computer is password protected.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)