Fuji Electric, Power energy counter

The 53U is a single-phase or three-phase communicating energy meter equipped with analog outputs. Ideal for energy measurement and monitoring applications for single-phase and three-phase LV / MV power systems by transmitting data via its RS485 digital output to a power management or monitoring system.

- Single-phase/2-wire and 3-wire, three-phase/3-wire and 4-wire systems.

- Measures simultaneously several variables of a heavy current power system: current, voltage, active, reactive and apparent power, active and reactive energy, power factor, frequency, etc.

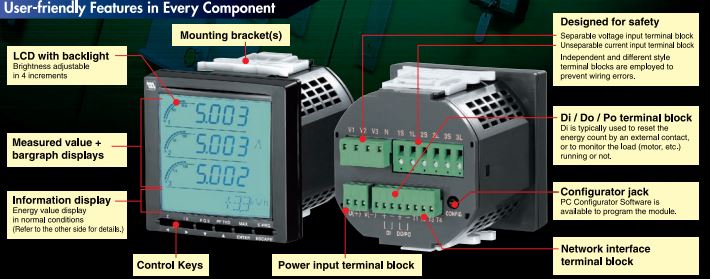

- Three line measured value/bargraph indicators plus energy count/info display

- Input range up to 480 Vac, 1 A or 5 A

- Primary voltage range: 50 – 400 000 V

- Primary current range: 1 – 20 000 A

- Auxiliary power input: 100-240V AC / 110-240V DC

- High accuracy (voltage/current: ±0.2 %, energy: ±0.5 %)

- Up to 31st harmonic distortion measurement

- 1/4 DIN (96 x 96 mm) panel size

- IP50 front panel - Programming lock to prevent unwanted configuration changes

- LCD backlight -4 digital displays

- Screw terminal block

- Logic input

- Modbus + open collector output (alarm or pulse)

- Analog output in option.

Fuji Electric model 53U multi power monitor overview.

- Single-phase/2-wire and 3-wire, three-phase/3-wire and 4-wire systems

- Three line measured value/bargraph indicators plus energy count/info display

- Modbus, Ao, Di/Do options

- Up to 31st harmonic distortion measurement

- Software lock

- IP 50 front panel.

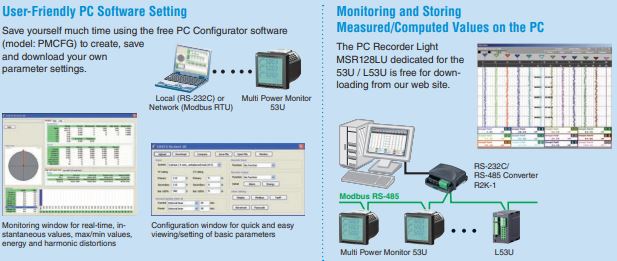

Fuji Electric model 53U is a 96-mm-square Multi LCD Power Monitor mounted on a panel surface. One model can be used for single-phase/2-wire and 3-wire, three-phase/3-wire and 4-wire systems. Users can freely choose and program major variables such like AC voltage/current, active/reactive power, power factor, AC frequency deviation, apparent power, active/reactive energy and up-to-the-31st harmonic distortions. Measured variables also include the maximum/minimum/ average values, in total of 500 types. Up to 1800 patterns of display combinations are available. All measured variables can be transmitted to the host PC via RS-485/Modbus RTU. Conversion factors, system configuration, interval times are programmable using the PC Configurator Software locally or remotely. Measured values, counter values, setting data are stored in the non-volatile memory at the power off.

An open collector output can be used for energy count pulse or limit alarm trip. Pulse rate for energy count can be speci ed. The contact output can be simulated for testing the connected device. External open collector input is typically used to reset energy count memory. The signal can be also monitored at the host system via Modbus, so that the host can start/ stop monitoring according to ON/OFF status of a load (e.g. motor running or not). Four analog output option (4-20 mA or 1-5 V) is also available instead of Modbus and Di/Do interface. Users can choose and program four among major variables, e.g. 1 VT plus 3 CT, to be converted into analog outputs, thus eliminating needs for four independent single function transducers.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)