Fuji Electric, PXF series - Digital temperature controller

- The largest bright color LCD on the market

- High speed sampling : 50 ms

- Fast processing : 100 ms

- Universal input

- Most compact class : 58 mm depth

- Multidrop master function (option)

Three models are available : PXF9 (96x96 mm), PXF5 (48x96 mm), PXF4 (48x48 mm).

LARGE NUMBER OF INPUT/OUTPUT SIGNALS :

- Universal input (RTD, thermocouple, voltage/current)

- Remote SV input (option)

- Current transformer (CT) input (option)

- Motorized valve position input (option)

- Output control (relay contact, SSR/SSC drive output, current/voltage) and in option (motorized valve control output, analog re-transmission output [current/voltage], heater burnout alarm, operating days alarm etc.)

CONTROL METHOD WITH AUTO TUNING :

- ON/OFF control

- PID control

- Fuzzy control

- 2-degrees-of-freedom PID control

- Self tuning

- Setpoint generator

- Heating/cooling control (option)

- Motorized valve control (option), etc.

PID AUTO TUNING.

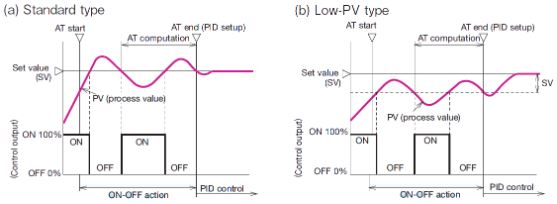

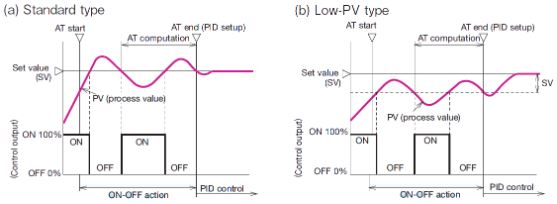

PID parameters are automatically set by the controller's measurement and computation function. This instrument provides 2 types of auto-tunning functions:

- the standart type (auto-tunning with SV used as reference)

- the low SV type (auto-tunning with the value 10% below SV used as reference)

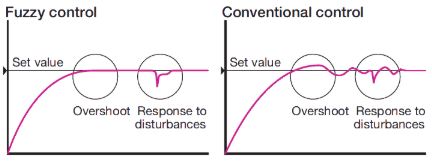

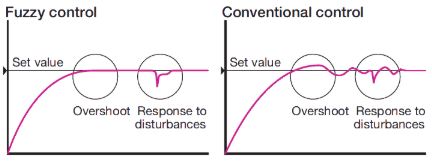

FUZZY CONTROL WITH AUTO TUNING

Fuzzy control is used to suppress overshoot so that the response to external distrubance is improved. By monitoring PV, overshoot is suppressed with startup time remaining unchanged. Also, disturbance can be settled quickly.

Comparison between fuzzy control and conventional control:

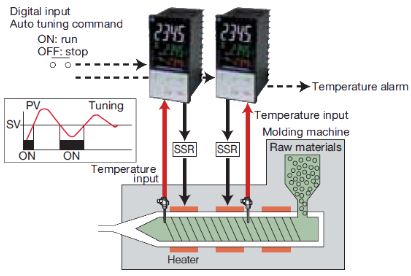

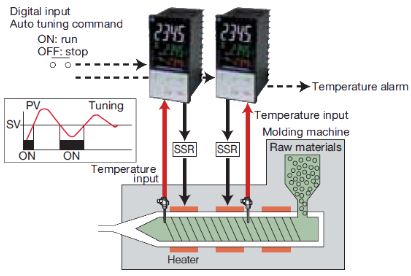

Start/stop of auto tuning can be commanded externally.

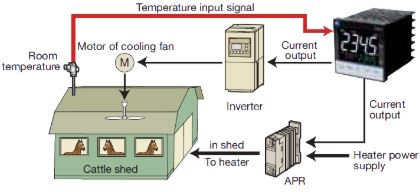

ENERGY SAVING IN LIVESTOCK BARNS.

- Both heating and cooling are controlled with only one temperature controller utilizing its 2 control outputs

- Power consumption can be curbed by controlling a cooling fan motor with inverter.

- High speed sampling : 50 ms

- Fast processing : 100 ms

- Universal input

- Most compact class : 58 mm depth

- Multidrop master function (option)

Three models are available : PXF9 (96x96 mm), PXF5 (48x96 mm), PXF4 (48x48 mm).

LARGE NUMBER OF INPUT/OUTPUT SIGNALS :

- Universal input (RTD, thermocouple, voltage/current)

- Remote SV input (option)

- Current transformer (CT) input (option)

- Motorized valve position input (option)

- Output control (relay contact, SSR/SSC drive output, current/voltage) and in option (motorized valve control output, analog re-transmission output [current/voltage], heater burnout alarm, operating days alarm etc.)

CONTROL METHOD WITH AUTO TUNING :

- ON/OFF control

- PID control

- Fuzzy control

- 2-degrees-of-freedom PID control

- Self tuning

- Setpoint generator

- Heating/cooling control (option)

- Motorized valve control (option), etc.

Fuji Electric advanced control functions.

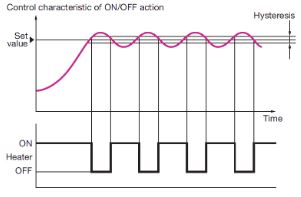

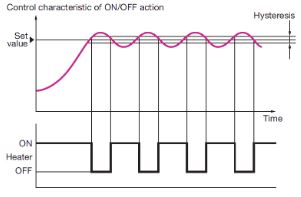

When process value (PV) is below the set value (SV), output is turned on and the heater is energized as shown below. When PV is SV, output is turned off and the heater is de-energized. In this way, output is turned on/off repeatedly with respect to the SV to keep the temperature constant. This method of control is called "on/off action" (or "two positions actions").

PID AUTO TUNING.

PID parameters are automatically set by the controller's measurement and computation function. This instrument provides 2 types of auto-tunning functions:

- the standart type (auto-tunning with SV used as reference)

- the low SV type (auto-tunning with the value 10% below SV used as reference)

FUZZY CONTROL WITH AUTO TUNING

Fuzzy control is used to suppress overshoot so that the response to external distrubance is improved. By monitoring PV, overshoot is suppressed with startup time remaining unchanged. Also, disturbance can be settled quickly.

Comparison between fuzzy control and conventional control:

Fuji Electric PXF series applications.

TEMPERATURE CONTROL OF PLASTIC MOLDING MACHINE.Start/stop of auto tuning can be commanded externally.

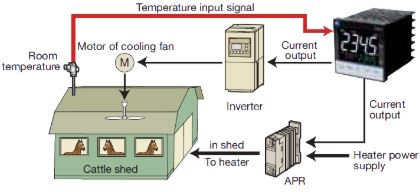

ENERGY SAVING IN LIVESTOCK BARNS.

- Both heating and cooling are controlled with only one temperature controller utilizing its 2 control outputs

- Power consumption can be curbed by controlling a cooling fan motor with inverter.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)