Fuji Electric, In-situ zirconia oxygen analyzers

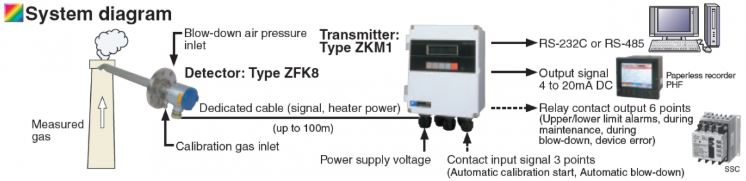

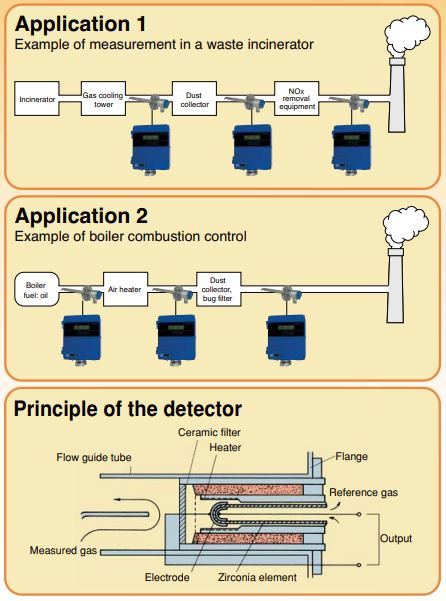

This oxygen analyzer is used to continuously measure oxygen concentration in combustion exhaust gas of industrial boilers or furnaces, and is ideally suited for combustion management and control, such as garbage incinerators and smallest to largest sized boilers, as combustion controllers, achieving a significant energy-saving effect.

The oxygen concentration control ensures complete combustion, thus reducing, SOx, and NOx emissions and helping prevent global warming and air pollution.

The transmitter is available as two case structures:

- IP66 version (ZKMA)The oxygen concentration control ensures complete combustion, thus reducing, SOx, and NOx emissions and helping prevent global warming and air pollution.

The transmitter is available as two case structures:

- IP67 version (ZKMB)

Industries : steel, power, petroleum/petrochemicals, ceramics, paper/pulp, food, and textile industries.

Combustion process : garbage incinerators and smallest to largest boilers, as combustion controllers.

Features.

- New Hart Protocole

- Reduction of excess combustion air Economy by increasing combustion efficiency

- Longevity of the combustion plant

- Easily replaceable zirconia element

High safety level:

- The converter cuts off the power supply for the detector when detecting a burnout of thermocouple.

- The converter also cuts off the power supply at emergency, in response to an external contact input.

- The key lock function prevents operational errors.

Fuji Electric IN-SITU ZIRCONIA OXYGEN ANALYZERS are energy Saving and Environmentally Friendly.

Fuji’s zirconia oxygen gas analyzers are widely used; not only in industries of high energy consumption, such as steel, power, petroleum/petrochemicals, ceramics, paper/pulp, food, and textile industries, but also in various combustion facilities, such as garbage incinerators and medium-tosmall sized boilers, as combustion controllers, achieving a significant energy-saving effect. The oxygen concentration control ensures complete combustion, thus reducing CO2, SOx, and NOx emissions and helping prevent global warming and air pollution.

No need for gas sampling devices and a rapid response with Fuji Electric.

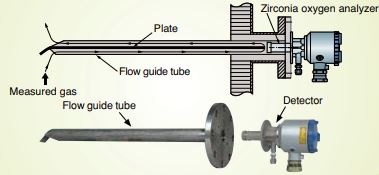

The flow guide tube design ensures a rapid response of 4 to 7 sec.

Various flow guide tubes, including one with a blow-down nozzle for high particulate levels, and models made of anti-corrosive materials, are available.

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)