Fuji Electric, S-Keeper 7TM

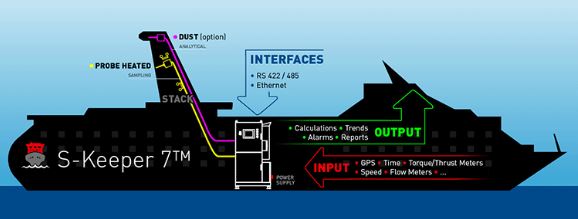

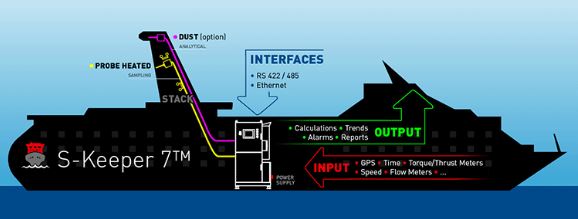

Also available as an alternative to our laser gas analyser is S-Keeper 7™ (S-K7™): a high-end extractive gas analyser for on-board continuous emission monitoring. It is fully IMO compliant; it has been certified according to RINA Rules, Pt. C, Ch 3, Sec 6; Lloyd’s Register Test Spec. 1; DNV Standard for Certification 2.4; and ClassNK.

- S-K7™ is simply the “State of the Art” of integrated analysis systems, fully compliant with applicable marine directives.

- S-K7™ is fully tailored to the Shipowner’s requests with particular focus on CaPex & OpEx balance.

- S-K7™ is integrated with a modern PEM Propulsion Efficiency Monitor, thus encompassing metered Fuel Consumption, Fuel Oil Viscosity, Thrust and Torque measuring Systems.

- Thanks to the specific engineering of this modular system, the S-K7™ installation is able to withstand the toughest marine environment.

- On-board maintenance is easy even for an unskilled operator, while the SPMP Spare Parts Management Program ensures the traceability of every single component and its availability on the ship’s course.

Monitoring exhaust gas emissions is crucial to demonstrating compliance with MARPOL Annex VI regulations on sulphur emissions. Additionally, an EU regulation* requires ship owners and operators to submit a monitoring plan for CO2 emissions by 31 August 2017. The time to act is now. For the maritime industry, continuous emissions monitoring systems (CEMS) are growing in popularity, as IMO guidelines** on exhaust gas cleaning systems (EGCS) prescribe them.

A certified, IMO-compliant analyser.

- Certified as per RINA Rules, Pt. C, Ch 3, Sec 6; Lloyd's Register Test Spec. 1; DNV Standard for Certification 2.4; and ClassNK.

- Compliant with Regulation (EU) 2015/757

A smart hub for monitoring and analysis.

- Able to analyse up to seven different substances

- Comes in seven types: Easy-S, Lite-S, Easy, Easy-N, Lite-N, Lite, and full

- Fully tailored to ship owners’ requests, with a focus on CapEx and OpEx balance to increase fuel economy while minimizing costs and air pollution.

Fuji Electric measurement and analytical technology.

The technology behind Fuji Electric laser gas analyser for ships is a product of its experience in developing air pollution monitoring and measurement equipment for industrial plants.

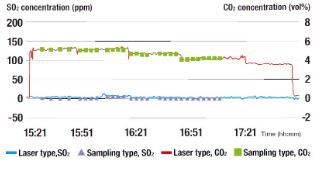

Fuji Electric’s laser gas analyser is capable of measuring and analysing both SO2 and CO2 in seconds. Its high-speed response time amounts to more precise, higher-resolution monitoring than conventional sampling analysers. The analyser determines in real time the state of exhaust gases after washing; thus, it optimizes the SOx scrubber’s pump operation based on alkali content in wash water. This leads to improved fuel economy and reduced operating costs.

Stable performance, longer maintenance cycle.

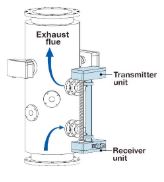

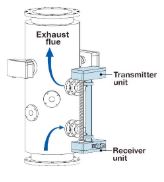

Fuji Electric’s laser gas analyser can be directly installed as a bypass stream for the exhaust flue. Its high anti-dust performance guarantees stable analysis and facilitates low maintenance.

Compactness.

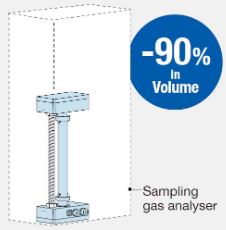

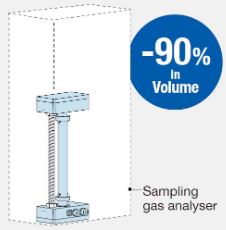

As part of the world’s smallest EGCS, Fuji Electric’s laser gas analyser is one-tenth the size of a conventional sampling analyser. Occupying less space gives it a major advantage over conventional sampling analysers and facilitates both retrofitting and installation in new ships.

The products tested conform to the certification’s requirements and are authorised for installation in the locations listed below:

- Temperature D: Open deck on a ship with ambient temperatures from -20°C to +70°C

- Humidity B: Anywhere on the ship with a humidity rate up to 100%

- Vibration B: Equipment such as combustion engine pumps and heir associated pumping system everywhere on the ship, including the deck and the open deck

- EMC B: Everywhere on the ship, including the deck and the open deck

- Enclosure C: Open deck, lower deck, lower plates in the engine room

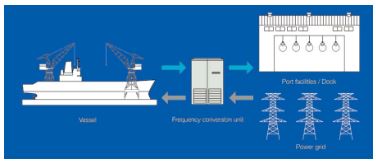

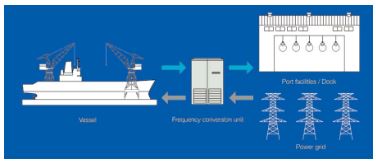

Frequency conversion unit Ship-to-shore two-way power supply system.

Effective use of surplus power : Facilitates power supply from both land to ship and ship to land (when testing generator load).

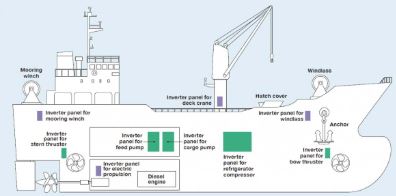

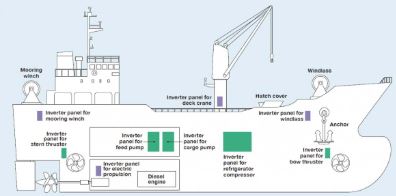

Drives and inverters Energy-saving equipment.

Electrification contributes to energy and labour savings, improving environmental performance:

- FRENIC-Eco Series: On-board fan, feed pump, cargo pump

- FRENIC-VG Series (Unit type, Stack type): Deck crane, deck equipment (e.g. windlass, mooring equipment) Electric propulsion, side thruster.

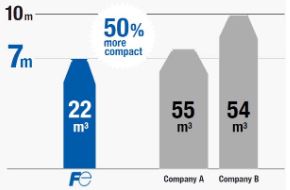

World’s smallest SOx scrubber Removes over 98% of SOx.

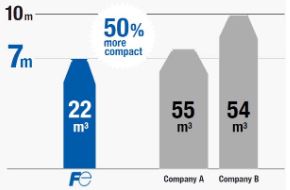

By adopting cyclone technology, Fuji Electric’s SOx scrubber keeps pressure loss to less than 1kPa and has achieved significant downsizing. Its scrubber is 50% more compact than other SOx scrubbers on the market: it is lightweight, facilitating installation in ships. It can remove over 98% of sulphur in exhaust gases. Its operation can be optimized based on engine load, minimizing fuel consumption and impact on operating costs.

On-board testing of a SOx scrubber for a main engine (MV Nadeshiko).

In March 2016, Fuji Electric provided the exhaust gas cleaning system for a test. That involved the installation of an exhaust gas cleaning system (EGCS) for a main engine on an operating new-build vessel and a practical test of a closed-loop mode. The test constituted a joint R&D effort that was supported and promoted by ClassNK and Imabari Shipbuilding Co., Ltd. It was the first time in Japan for a SOx scrubber to be installed on a bulk carrier.

ELECTROSTATIC PRECIPITATOR FOR MARINE ENGINES.

For 30 years, Fuji Electric has been a leading provider of electrostatic precipitators (ESPs) for tunnel ventilation systems. The company operates around 50 facilities in Japan and overseas.

- Electrostatically removes particulate matter (PM)

- Low pressure drop results in minimum impact on engine

- Removes ultrafine PM 1 micron or less in diameter

- S-K7™ is simply the “State of the Art” of integrated analysis systems, fully compliant with applicable marine directives.

- S-K7™ is fully tailored to the Shipowner’s requests with particular focus on CaPex & OpEx balance.

- S-K7™ is integrated with a modern PEM Propulsion Efficiency Monitor, thus encompassing metered Fuel Consumption, Fuel Oil Viscosity, Thrust and Torque measuring Systems.

- Thanks to the specific engineering of this modular system, the S-K7™ installation is able to withstand the toughest marine environment.

- On-board maintenance is easy even for an unskilled operator, while the SPMP Spare Parts Management Program ensures the traceability of every single component and its availability on the ship’s course.

Monitoring exhaust gas emissions is crucial to demonstrating compliance with MARPOL Annex VI regulations on sulphur emissions. Additionally, an EU regulation* requires ship owners and operators to submit a monitoring plan for CO2 emissions by 31 August 2017. The time to act is now. For the maritime industry, continuous emissions monitoring systems (CEMS) are growing in popularity, as IMO guidelines** on exhaust gas cleaning systems (EGCS) prescribe them.

A certified, IMO-compliant analyser.

- Certified as per RINA Rules, Pt. C, Ch 3, Sec 6; Lloyd's Register Test Spec. 1; DNV Standard for Certification 2.4; and ClassNK.

- Compliant with Regulation (EU) 2015/757

A smart hub for monitoring and analysis.

- Able to analyse up to seven different substances

- Comes in seven types: Easy-S, Lite-S, Easy, Easy-N, Lite-N, Lite, and full

- Fully tailored to ship owners’ requests, with a focus on CapEx and OpEx balance to increase fuel economy while minimizing costs and air pollution.

Fuji Electric world of Marine Technologies.

Fuji Electric is re-applying its core technologies and expertise from the land to the sea. Through optimal integration of proprietary technology and other products and technologies, Fuji Electric has created a new value-added solution for ships.

Fuji Electric measurement and analytical technology.

The technology behind Fuji Electric laser gas analyser for ships is a product of its experience in developing air pollution monitoring and measurement equipment for industrial plants.

Laser gas analyzer: Achieving optimized control with Fuji Compact, high speed, accurate, low-maintenance laser gas analyzer.

Fast, accurate analysis.

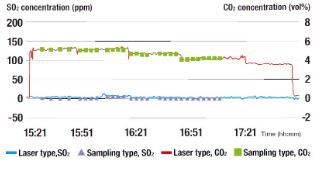

Fuji Electric’s laser gas analyser is capable of measuring and analysing both SO2 and CO2 in seconds. Its high-speed response time amounts to more precise, higher-resolution monitoring than conventional sampling analysers. The analyser determines in real time the state of exhaust gases after washing; thus, it optimizes the SOx scrubber’s pump operation based on alkali content in wash water. This leads to improved fuel economy and reduced operating costs.

Stable performance, longer maintenance cycle.

Fuji Electric’s laser gas analyser can be directly installed as a bypass stream for the exhaust flue. Its high anti-dust performance guarantees stable analysis and facilitates low maintenance.

Compactness.

As part of the world’s smallest EGCS, Fuji Electric’s laser gas analyser is one-tenth the size of a conventional sampling analyser. Occupying less space gives it a major advantage over conventional sampling analysers and facilitates both retrofitting and installation in new ships.

Fuji Electric ressure transmitters: marine type approval.

The FCX-AIII (AII V5) and FCX-AII series received DNV-GL marine-type approval.

The products tested conform to the certification’s requirements and are authorised for installation in the locations listed below:

- Temperature D: Open deck on a ship with ambient temperatures from -20°C to +70°C

- Humidity B: Anywhere on the ship with a humidity rate up to 100%

- Vibration B: Equipment such as combustion engine pumps and heir associated pumping system everywhere on the ship, including the deck and the open deck

- EMC B: Everywhere on the ship, including the deck and the open deck

- Enclosure C: Open deck, lower deck, lower plates in the engine room

Fuji Electric monitoring and control technology.

At Fuji Electric, we offer a range of total solutions for factory automation systems: solutions that achieve energy savings and support efficient manufacturing processes.Frequency conversion unit Ship-to-shore two-way power supply system.

Effective use of surplus power : Facilitates power supply from both land to ship and ship to land (when testing generator load).

Drives and inverters Energy-saving equipment.

Electrification contributes to energy and labour savings, improving environmental performance:

- FRENIC-Eco Series: On-board fan, feed pump, cargo pump

- FRENIC-VG Series (Unit type, Stack type): Deck crane, deck equipment (e.g. windlass, mooring equipment) Electric propulsion, side thruster.

Fuji Electric scrubber technology.

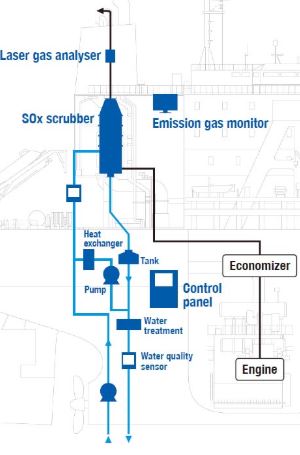

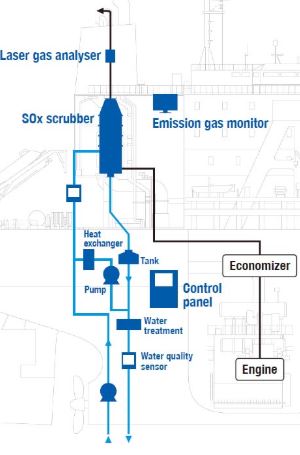

Fuji Electric SOx scrubber for ships utilizes cleaning technologies and is the result of our extensive experience in fuel cell development and geothermal power generation. Fuji Electric’s SOx scrubber for ships is the very first in the world to use cyclone technology. Within the scrubber, a highly diffused spray of wash water increases contact between exhaust gases and liquid droplets, removing SOx by absorption. The cyclone method makes a mixing plate (which needs regular maintenance) unnecessary; so it also makes for lower maintenance costs.

World’s smallest SOx scrubber Removes over 98% of SOx.

By adopting cyclone technology, Fuji Electric’s SOx scrubber keeps pressure loss to less than 1kPa and has achieved significant downsizing. Its scrubber is 50% more compact than other SOx scrubbers on the market: it is lightweight, facilitating installation in ships. It can remove over 98% of sulphur in exhaust gases. Its operation can be optimized based on engine load, minimizing fuel consumption and impact on operating costs.

On-board testing of a SOx scrubber for a main engine (MV Nadeshiko).

In March 2016, Fuji Electric provided the exhaust gas cleaning system for a test. That involved the installation of an exhaust gas cleaning system (EGCS) for a main engine on an operating new-build vessel and a practical test of a closed-loop mode. The test constituted a joint R&D effort that was supported and promoted by ClassNK and Imabari Shipbuilding Co., Ltd. It was the first time in Japan for a SOx scrubber to be installed on a bulk carrier.

Fuji Electric electrostatic technology.

Based on Fuji electrostatic technology for tunnel ventilation systems, they are currently developing an electrostatic precipitator for ships.ELECTROSTATIC PRECIPITATOR FOR MARINE ENGINES.

For 30 years, Fuji Electric has been a leading provider of electrostatic precipitators (ESPs) for tunnel ventilation systems. The company operates around 50 facilities in Japan and overseas.

- Electrostatically removes particulate matter (PM)

- Low pressure drop results in minimum impact on engine

- Removes ultrafine PM 1 micron or less in diameter

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)